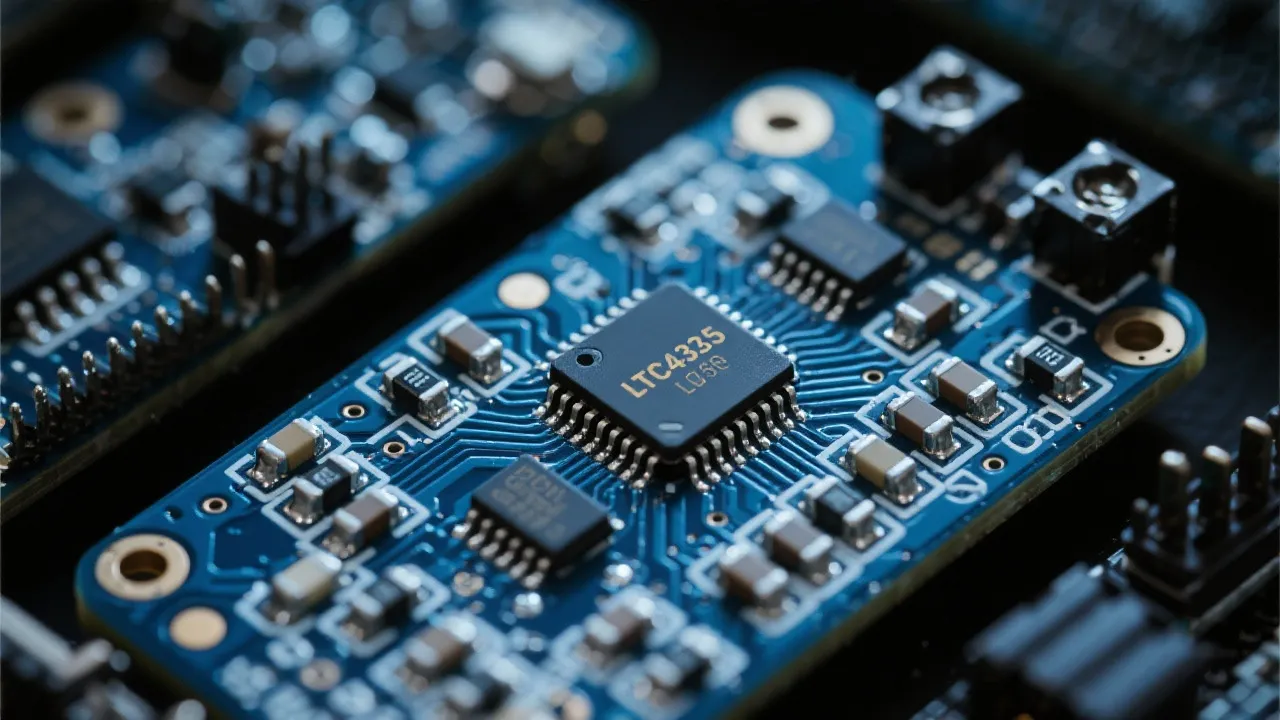

The Ltc4365 is a critical power controller designed to safeguard electronic circuits from harmful fault conditions. Employed extensively in the electronics industry, it serves to prevent overvoltages, reverse voltages, and under-voltages, ensuring system stability and extending the lifespan of devices. This article delves into its functions, advantages, and application areas.

The Ltc4365 is a power controller chip created by Analog Devices renowned for its robust protective functionality in electronic circuits. The significance of Ltc4365 lies in its ability to offer comprehensive protection against overvoltage, reverse voltage, and under-voltage conditions, which are critical challenges impacting the performance and longevity of electronic systems. This capability makes it a pivotal component in various industries that rely heavily on stable electronic operations.

The Ltc4365 is designed with a range of features that help enhance its utility in protecting electronic circuits. It operates across a wide input voltage range, typically from 4V to 80V, allowing it to be used in a diverse array of applications. One of its primary roles is to ensure supply compliance by preventing over-voltages, which could otherwise lead to circuit damage. Furthermore, the Ltc4365 is equipped with robust reverse voltage and under-voltage lockout capabilities, providing comprehensive protection for sensitive electronic components.

| Feature | Description |

|---|---|

| Wide Voltage Range | Operates effectively from 4V to 80V, suitable for a broad range of devices. |

| Over-Voltage Protection | Prevents damage from voltage spikes by actively clamping excess voltage. |

| Reverse Voltage Protection | Blocks negative voltage to safeguard the system from accidental power reversal. |

| Under-Voltage Lockout | Disables the system when voltage drops below a critical level to avoid damage. |

The Ltc4365 finds applications in various sectors where electronic stability and protection are vital. A primary use case is in automotive electronics, where power stability is crucial due to the harsh operational environment. Similarly, the Ltc4365 is employed in the industrial sector, specifically in factories where equipment is constantly exposed to fluctuating power supply conditions. This versatility in application underscores the chip’s importance in both commercial and industrial settings.

In the automotive sector, the Ltc4365 plays a critical role in protecting sensitive components from voltage surges that may occur due to the vehicle's electrical system. Cars today are increasingly reliant on advanced electronic systems, including infotainment setups, navigation assistance, and various control systems that regulate engine performance and safety features. As vehicles become more electrified with battery management systems and electric powertrains, ensuring the integrity of these systems against potential electrical disruptions is essential.

Industrial settings often encounter unstable power conditions, making the Ltc4365 an invaluable asset in these environments. Equipment such as programmable logic controllers (PLCs), sensors, and actuators are particularly susceptible to damage from voltage spikes or drops. Implementing the Ltc4365 helps to minimize downtimes due to equipment failure, ultimately contributing to increased productivity and reduced maintenance costs. The robustness of the Ltc4365 in mitigating electrical noise and transients further enhances its suitability for industrial automation systems.

Beyond automotive and industrial uses, the Ltc4365 also finds utility in the consumer electronics market. Devices such as laptops, smart home technologies, and mobile phones must endure various electrical fluctuations that could compromise performance. By incorporating the Ltc4365, manufacturers can assure end-users of the reliability and longevity of their products, thus boosting consumer confidence. As wireless charging technologies become prevalent, the need for such protective measures is heightened due to the unique vulnerabilities posed by these systems.

When integrating the Ltc4365 into electronic designs, it is crucial to follow specific guidelines to maximize performance and reliability. The integration process includes careful attention to the circuit layout to minimize noise and ensure adequate thermal management. Proper placement of bypass capacitors is essential to mitigate voltage transients while ensuring that all conditions meet the specified thresholds for voltage protection. This proactive approach not only bolsters system reliability but also enhances overall efficiency.

Integrating the Ltc4365 into a circuit requires careful planning. Designers should ensure that they understand the electrical characteristics of both the Ltc4365 and the components it interfaces with. Evaluating the input voltage specifications can help determine the necessary variations and tailoring the input/output components to withstand the expected operational stresses. For instance, evaluating the current handling capacity and the resultant thermal performance becomes vital to prevent heat buildup that could compromise the protection features of the device.

The layout of the circuit is critical to the success of implementing the Ltc4365. Designers should minimize the loop areas to reduce electromagnetic interference (EMI) and stray inductance. By using short and wide traces for power paths and keeping sensitive signal traces away from noisy signals, the risk of erroneous voltage readings can be substantially mitigated. Additionally, adequate grounding practices should be employed to ensure that ground loops do not adversely affect performance.

Thermal management is paramount in ensuring that the Ltc4365 functions reliably throughout its operational lifetime. Designers must assess the heat dissipation requirements based on expected power losses and anticipated environmental conditions. Implementing thermal reliefs, heat sinks, and adequate ventilation can significantly enhance the chip’s performance by maintaining operating levels within specified limits. Active cooling methods may also be considered for high-current applications where heat generation could exceed passive cooling options.

Q: What is the primary advantage of using Ltc4365?

A: The Ltc4365 acts as a robust barrier against potentially damaging voltage conditions, thereby significantly increasing the protection and reliability of electronic devices.

Q: Can Ltc4365 handle high current loads?

A: While primarily designed for voltage protection, the Ltc4365 can handle moderate current loads, but for higher currents, additional components may be necessary. The maximum current specification must be adhered to in accordance with the specific design applications.

Q: Where can I source Ltc4365 chips?

A: Ltc4365 chips are typically available through authorized electronic component distributors. It is recommended to procure them from reputable suppliers to ensure authenticity and product support. Online platforms, as well as brick-and-mortar stores, can offer competitive pricing and availability, which is beneficial for bulk users.

Q: Are there any common applications where Ltc4365 is used?

A: Yes, common applications include automotive systems for power supply stability, industrial automation equipment for voltage resilience, and consumer electronics to protect against voltage spikes that could damage sensitive circuits.

Q: Can I use Ltc4365 in outdoor electronic systems?

A: Yes, the Ltc4365 is suitable for outdoor applications; however, during integration, considerations regarding environmental factors such as temperature extremes and moisture exposure must be accounted for to ensure the longevity of the device.

The Ltc4365 stands as a pivotal solution in the ongoing quest to stabilize and protect electronic applications from variable power conditions. By offering comprehensive defense against numerous voltage-related issues, it underscores its indispensable nature in contemporary electronic circuit design. As industries continue to evolve, integrating such critical components as the Ltc4365 becomes imperative to maintaining uninterrupted and efficient electronic operations.

As beneficial as the Ltc4365 is, designers may encounter challenges when integrating it into their systems. These challenges can potential impact performance if not carefully managed.

In electronic systems, noise generated by nearby components or switching operations can lead to inaccurate readings and disrupt system functionality. The identification and mitigation of such noise sources are paramount. To combat this, placing decoupling capacitors close to the power pins of the Ltc4365 helps shield the component from high-frequency noise. Furthermore, using ferrite beads on power supply lines can help filter out undesirable high-frequency signals.

Implementing thermal protection is integral to the longevity of the Ltc4365. An effective strategy is to utilize a thermal monitoring system that can shut down the application if temperatures exceed safe limits. Failure to address potential thermal overload can lead to detrimental operational speed degradation or complete functionality loss of the device.

When using the Ltc4365, it’s important to analyze scenarios where reverse current may flow, particularly during power down conditions. In such cases, placing appropriate diode configurations in conjunction with the Ltc4365 can offer additional layers of protection against back-voltage situations, securing sensitive components from damage. Designers should evaluate the need for additional diodes based on their specific application requirements.

The Internet of Things (IoT) revolution is expanding the landscape of electronic applications, heightening the need for dependable and resilient power management solutions. As we delve into a future increasingly populated by smart devices with complex functionalities—from connected home appliances to industrial IoT sensors—the role of protective controllers like the Ltc4365 becomes more critical. Here, we explore several ways the Ltc4365 aligns with trends in this direction:

In smart homes, various devices continually communicate and rely on power stability to function seamlessly. The Ltc4365 can ensure that devices such as smart light bulbs, energy management systems, and security cameras are safeguarded against unexpected voltage fluctuations. As the reliability of these systems is paramount, the implementation of the Ltc4365 will significantly contribute toward enhancing user experience and system integrity.

The rise of wearable devices has prompted manufacturers to explore miniature and efficient power solutions. The Ltc4365 can be implemented in these compact systems, providing the necessary protection without occupying excess space. The growing demand for wearables has made reliability a key concern for manufacturers, as product failure in such applications can lead to poor user experiences. The use of Ltc4365 in wearables serves to mitigate such risks through robust voltage protection.

As factories transition towards automation and embrace smart manufacturing technologies, the need for reliable power management is becoming more pressing. The Ltc4365 is poised to play a vital role in protecting critical industrial IoT components that measure operational statistics, enabling predictive maintenance and boosting overall operational efficiency. As industries adapt to this technological shift, the significance of incorporating effective protective solutions like the Ltc4365 cannot be overstated.

The Ltc4365 represents a cornerstone in modern electronic design, addressing essential requirements for voltage protection in various applications. Its robust functionalities uniquely position it to mitigate risks associated with over-voltage, under-voltage, and reverse voltage conditions. Whether in automotive, industrial, consumer electronics, or emerging IoT applications, integrating the Ltc4365 offers a vital line of defense for electronic systems. As we embrace an era of smarter devices and interconnected systems, the importance of maintaining reliability through protective measures will continue to grow. Ultimately, the Ltc4365 embodies not just a component, but a comprehensive solution vital for the advancement of electrical and electronic technology.

Navigating Online Bank Accounts

Understanding AC 380 Systems

Discovering the Tiguan's Versatility

Integrating Usaepay with WooCommerce

Understanding BA 270 Concepts

Understanding AMQ 6209 in Detail

Understanding Hydac RF Filtration Systems

Understanding the BA 270 Course

Navigating the Realm of Business Communication