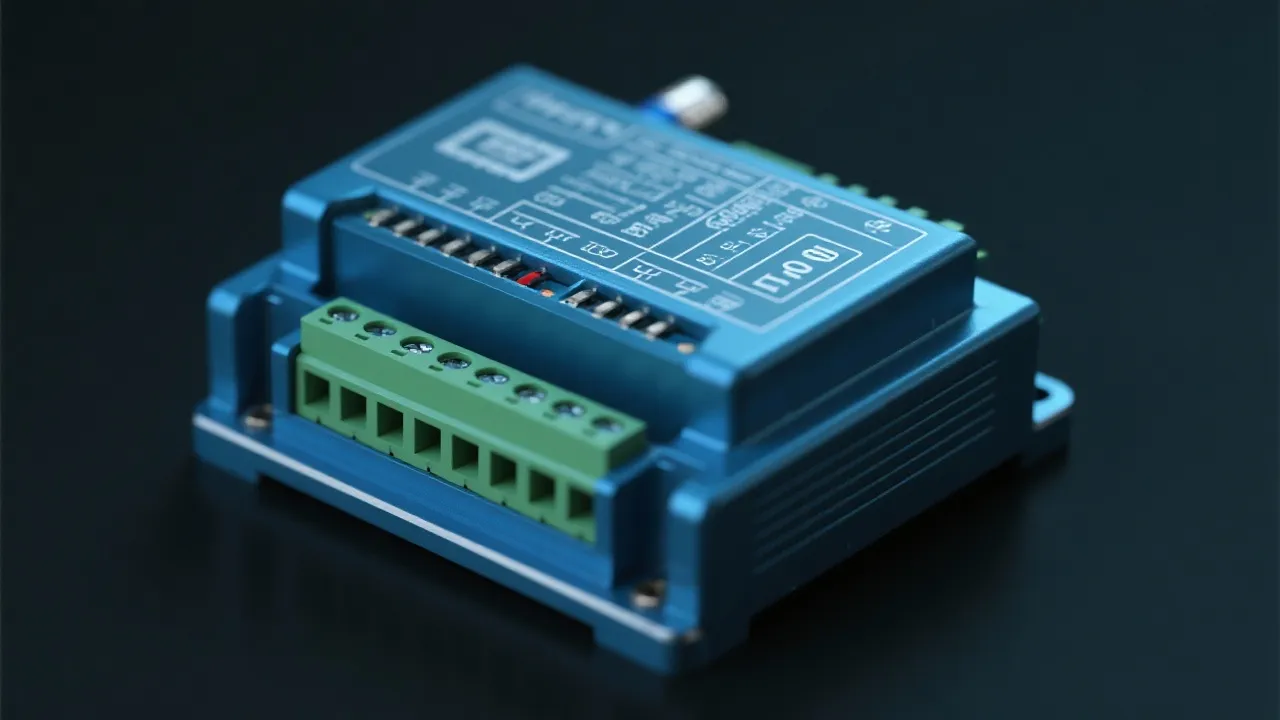

The DRV8704 is a prominent motor driver integrated circuit, widely recognized for its versatility in managing both brushed DC and stepper motors. This article delves into the features, applications, and technical specifications of the DRV8704, offering a detailed analysis for industry professionals. Its compatibility with various power supplies and protection mechanisms makes it an indispensable tool in numerous industrial applications.

The DRV8704 motor driver IC is an advanced component engineered to facilitate the smooth control of both brushed DC and stepper motors. It is renowned for its adaptability and efficiency, making it a preferred choice in a vast array of industrial settings. The versatile nature of the DRV8704 aligns well with demands for high-performance motor control systems, offering scalable solutions for complex motion control tasks. As industries move towards greater automation, the DRV8704 stands out by providing refined motor control that enhances operational performance while optimizing energy consumption.

The DRV8704 boasts a variety of features that enhance its functionality and usability in different applications. As a current-controlled and pulse-width modulation (PWM) driver, it supports voltages up to 40V and provides an interface that accommodates multiple microcontrollers—affording users flexibility in component selection. This motor driver is built with protection features such as overcurrent protection, over-temperature protection, and short-circuit protection, ensuring safe and reliable operation across its deployed systems. Furthermore, the DRV8704 offers advanced control methods including constant current regulation—allowing for precise motor control under varying load conditions, which is crucial for applications requiring enhanced responsiveness.

The applications of the DRV8704 are diverse, given its ability to drive both DC and stepper motors seamlessly. It finds extensive use in robotics, where precise motor control is necessary for movement and articulation. In industrial automation systems, it aids in driving conveyors, assembly lines, and automated guided vehicles (AGVs). The print industry utilizes the DRV8704 in printers to ensure high-quality motion control for print head movement, leading to accurate color distribution and image quality. In CNC machinery, the driver manages precise movement of cutting tools and workpieces. The adaptability of the DRV8704 in interfacing with various control systems underscores its importance in environments where precision and reliability are paramount.

In the industrial automation landscape, efficiency and precision are the cornerstones of operational excellence. The DRV8704 motor driver aids in achieving these by providing controlled torque and speed to motors, contributing to improved productivity in manufacturing processes. Its robust architecture and flexible programming interface allow engineers to tailor solutions specific to their operational requirements. This level of customization can lead to significant reductions in production downtime and maintenance costs. Additionally, the incorporation of feedback mechanisms, such as encoders, ensures that the motor’s performance is closely monitored, allowing for real-time adjustments that optimize operation. Moreover, the capability for energy-efficient performance attracts industries focused on sustainability, as the DRV8704 facilitates reduced power consumption during both idle and active states.

Despite its myriad benefits, integrating the DRV8704 with existing systems can pose challenges. Engineers need to consider power supply compatibility and mutual impedance matching to ensure seamless functionality. The wide voltage range is advantageous; however, maintaining stable performance across different motor types and supply voltages can require meticulous circuit design. Additionally, careful planning in circuit design and signal processing is crucial to mitigate electromagnetic interference (EMI), which can affect performance. Effective grounding techniques and shielded cables may be necessary to ensure minimal noise during operation. Troubleshooting compatibility issues also may involve reviewing signal processing algorithms to align with the DRV8704’s operational characteristics; this step can be essential in applications requiring synchronized control across multiple motors. Alongside these considerations, the technical skill set of the engineering team is a vital determinant in successful integration.

| Features | DRV8704 | Comparable Motor Driver |

|---|---|---|

| Voltage Range | 6.5V to 40V | 5V to 30V |

| Current Rating | Up to 8A | Up to 5A |

| Protection Mechanism | Yes, multiple types | Basic protection |

| Control Method | PWM and current control | PWM only |

| Microcontroller Compatibility | Multiple interfaces available | Limited interfaces |

| Size | Compact EPD package | Larger footprint |

Implementing the DRV8704 in a system involves several detailed steps:

The DRV8704 is suitable for driving both brushed DC and stepper motors. It efficiently handles different control requirements associated with each motor type.

It incorporates an automatic over-current protection mechanism to prevent damage during high-load conditions, safeguarding not just the driver but also the connected motors from sudden failures.

Yes, it can be integrated with Arduino boards using appropriate interfacing libraries. Many users have successfully created driver modules that facilitate simple integration with available code repositories for hobbyist and advanced projects alike.

Absolutely, the DRV8704's design supports high current ratings, permitting its use in high torque applications such as robotic arms or industrial conveyor systems, provided that thermal management standards are maintained to prevent overheating.

For high-power applications, a heat sink may be recommended alongside carefully designed airflow management to dissipate heat effectively and ensure stable operation under load.

Yes, a single DRV8704 can control multiple motors with shared inputs, but each motor must operate within the rated power specifications to avoid overloading the driver.

The DRV8704 motor driver stands out as a reliable and multifaceted solution for controlling motors in diverse industrial environments. Its robust design, combined with a comprehensive set of features, makes it an essential component for driving innovation and efficiency across numerous technological applications. Whether in robotics, CNC machinery, or automation systems, the DRV8704 continues to exemplify precision and reliability in motor control technology. As industries increasingly depend on efficient motor solutions, the adoption of the DRV8704 is poised to grow, further cementing its role as a leading choice in the realm of motor drivers. Ongoing advancements in technology will likely inspire continued enhancements to the DRV8704’s capabilities, driving it to evolve alongside emerging industry needs and technological challenges.

In recent years, advancements in motor control technology have fostered remarkable improvements in efficiency, precision, and fault tolerance. The future landscape of motor control will likely be shaped by trends and specific technological advancements designed to enhance the capabilities of drivers like the DRV8704. One important aspect is the growing emphasis on energy efficiency, as industries strive for sustainable practices. Future motor drivers will likely introduce algorithms to optimize power consumption actively, adapting to real-time load conditions.

Furthermore, the increasing integration of AI and machine learning techniques promises improved operational efficiency by enabling predictive maintenance practices and automation. Combining these technologies with motor drivers can facilitate intelligent monitoring systems capable of interpreting operational data to foresee potential failures and ensure uninterrupted operations, thereby maximizing uptime.

Another important area of development will involve enhanced safety features, including more sophisticated sensing technologies that can predict over-temperature or overcurrent scenarios before they lead to component failure. Improvements in component materials, such as the advent of Silicon Carbide (SiC) technology, may also allow for higher efficiency in power conversion, further bolstering the capabilities of future motor controllers.

In summary, the ongoing evolution of motor control technology represents a critical area for future engineering innovation. As industries adapt to these changes, components like the DRV8704 will continue to be fundamental enablers of performance, flexibility, and sustainability in the ever-changing industrial landscape.

Navigating Online Bank Accounts

Understanding AC 380 Systems

Discovering the Tiguan's Versatility

Integrating Usaepay with WooCommerce

Understanding BA 270 Concepts

Understanding AMQ 6209 in Detail

Understanding Hydac RF Filtration Systems

Understanding the BA 270 Course

Navigating the Realm of Business Communication