The DRV8704 is a prominent motor driver controller widely used in various applications. Its ability to handle complex drive systems with high efficiency makes it indispensable in industries. This article delves into its technical specifications, functionalities, and potential impact on modern engineering solutions, offering insights from an expert perspective on its unique advantages.

In the world of electronic engineering and robotics, the DRV8704 plays a crucial role as a highly effective motor driver controller. Designed to cater to advanced drive systems, it offers precision control over motor operations, ensuring both reliability and performance. With industrial applications demanding increasingly sophisticated solutions, the DRV8704 emerges as a pivotal component, enabling smoother and more efficient motor control. The relevance of the DRV8704 extends beyond simple motor operations; it integrates advanced features that allow engineers to implement complex motion systems and drive different types of motors effortlessly.

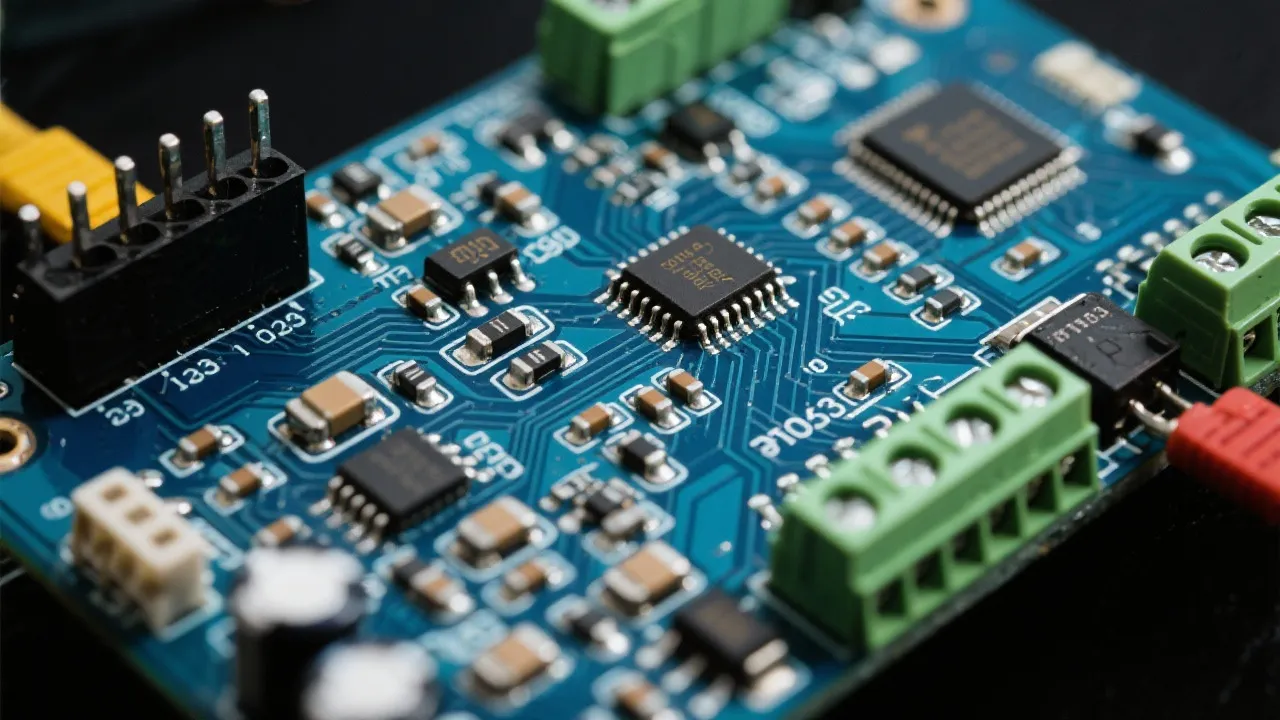

The DRV8704 stands out for its versatile capabilities, tailored for a wide range of applications. It supports dual H-bridge configurations, which are essential for managing different motor drive systems. This flexibility allows for reduced circuit complexity, resulting in more compact and cost-effective designs. Additionally, the integration of current regulation features enhances overall system longevity by safeguarding against overcurrent conditions. The device operates efficiently under varying loads, enabling robust performance across different scenarios, which is imperative in today’s dynamic environments.

Moreover, the DRV8704's specifications also include a high current handling capability that is particularly beneficial for applications requiring immediate torque response, such as robotics and drone technology. This characteristic, along with its small footprint, sets a foundation for design engineers to innovate and experiment with new applications.

The applicability of the DRV8704 spans several fields, from automation systems to consumer electronics and industrial machinery. In robotics, for instance, its precise control facilitates motion systems, enabling robots to perform complex tasks with elevated accuracy. The DRV8704 is instrumental in the development of robotic arms, autonomous vehicles, and drones, where exact positioning and responsive control are vital. In industrial automation, it finds usage in conveyor systems, robotic manufacturing cells, and smart factory applications, providing reliable motor control that ensures high productivity with minimal downtime.

Moreover, the DRV8704 is increasingly being integrated into the Internet of Things (IoT) devices, where it helps achieve precise control over motors in smart appliances, actuators, and other interactive technology. By enabling real-time control and feedback, the DRV8704 allows these devices to operate efficiently within networked ecosystems, improving performance, optimization, and user engagement.

In consumer electronics, advanced washing machines and robotic vacuum cleaners benefit from the DRV8704's advanced control features, leading to enhanced functionality and operational smoothness. Its adoption in sectors that require low noise and high efficiency underscores its versatility and reliability.

| Feature | Advantages | Disadvantages |

|---|---|---|

| Precision Control | Enhanced accuracy and operational efficiency, allowing for nuanced motor control in demanding applications. | Requires comprehensive understanding for optimal use; may not be straightforward for less experienced designers. |

| Integrated Protection | Increased system lifespan and reliability. Protection mechanisms help prevent potential failures during operation. | Potential complexity in integrating protection features into designs; may necessitate additional learning or implementation time. |

| Adaptive Blanking | Reduced operation noise and enhanced user experience; crucial for applications in silent environments. | May require additional configuration time; initial setup might be cumbersome for non-experts. |

| Wide Voltage Range | Greater application versatility, accommodating various types of motors and power supplies. | Possibility of increased cost due to broad support; extensive testing may be needed to ensure compatibility across voltage levels. |

| High Current Handling | Supports applications requiring quick torque response, beneficial in high-performance scenarios. | Higher current demands may necessitate advanced thermal management strategies, potentially complicating designs. |

As industry experts, we recognize that the implementation of the DRV8704 in a project involves meticulous planning and a deep understanding of its working principles. While its specifications promise high efficiency and multifunctionality, harnessing these capabilities requires knowledge and experience. Understanding the specific application requirements is crucial to capitalize on the DRV8704’s full potential, ensuring optimal performance and reliability. Additionally, as technology continues to evolve, staying abreast of trends in motor control technologies can provide insights into how to best apply the DRV8704 in future projects.

One critical aspect that engineers often overlook is the importance of thermal management when using the DRV8704. As it operates at higher currents, effective heat dissipation strategies must be in place to prevent unexpected shutdowns or damage to the motor driver. Factors such as PCB layout, heat sink integration, and ambient temperature can significantly influence the performance of the DRV8704. Engaging in thorough thermal analysis and incorporating appropriate cooling solutions will lead to better long-term performance and reliability.

Additionally, calibration of the motor control parameters according to specific application needs is vital. Advanced motion profiles may require personalized tuning of PWM frequencies and current limits, contributing to improved iteration cycles and achieving desired performance levels. This aspect of customization is where the expertise of engineers shines, transforming the DRV8704 into an optimal solution tailored for the intricate demands of diverse applications.

Q1: Can the DRV8704 be used in consumer applications?

A1: Yes, the DRV8704 is well-suited for consumer products that demand precise motor control, such as high-end audio equipment and advanced home automation systems. Its features cater well to the requirements of applications where user experience is paramount.

Q2: What makes the DRV8704 superior to other motor controllers?

A2: Its combination of protection features, adaptability, and efficient PWM control differentiates it, providing enhanced performance and versatility in various applications. Additionally, its ability to operate silently makes it a preferred choice across applications that value a noise-free environment.

Q3: Are there particular industries where the DRV8704 is very prevalent?

A3: The DRV8704 is prevalent in industries like robotics, automotive, and industrial equipment manufacturing, where precision and reliability are paramount. Its versatility also allows it to be incorporated in consumer electronics, IoT devices, and smart technologies, expanding its market reach.

Q4: How does the DRV8704 contribute to energy efficiency?

A4: By optimizing power management and reducing waste through precise control, the DRV8704 supports energy-efficient operations, which are beneficial in both ecological and economic terms. Its ability to operate within a wide voltage range allows it to effectively match power supply characteristics without incurring excess consumption or losses.

Q5: What considerations should designers keep in mind when integrating the DRV8704?

A5: Designers should consider the thermal management requirements, the electrical characteristics of motors used, and the integration of safety features. Proper thermal management and layout design are crucial for ensuring long-term reliability. Additionally, thorough testing under various load conditions can provide insights into how the DRV8704 will perform in the intended environment.

The landscape of motor control technology is ever-evolving, and the DRV8704 is positioned as a forward-thinking solution. As applications demand higher precision and efficiency, the DRV8704 holds the potential to adapt and meet these requirements. The continued miniaturization of electronic components, along with the drive for enhanced performance, will likely lead to wider adoption of integrated motor driver controllers like the DRV8704.

Moreover, the increasing integration of machine learning and artificial intelligence into engineering processes hints at exciting developments for the future of motor control. Imagine a scenario where motor control systems equipped with DRV8704 can autonomously adjust to dynamic load conditions or user preferences, optimizing performance in real-time. This will not only improve productivity but also pave the way for innovations in automation and robotics.

As developers strive to enhance system efficiencies and reduce costs, solutions like the DRV8704 will play an essential role in powering the next generation of technologies. Its advanced features and adaptability position it at the forefront of motor control innovations, signaling a promising future for engineers and designers alike. The commitment to continuous improvement and adapting to emerging technologies will ensure that the DRV8704 remains a key player in the domain of motor control.

In conclusion, the DRV8704 remains an indispensable tool in the arsenal of engineers and designers committed to developing sophisticated, efficient, and high-performance systems. Its multifaceted capabilities and built-in protective features continue to redefine the standards of modern motor control, offering the promise of advancement in numerous technical domains. As we move towards a more automated world and embrace innovations in technology, components like the DRV8704 will be pivotal in shaping the future landscape of engineering, providing the versatility, precision, and reliability needed across a myriad of applications.

Navigating Online Bank Accounts

Understanding AC 380 Systems

Discovering the Tiguan's Versatility

Integrating Usaepay with WooCommerce

Understanding BA 270 Concepts

Understanding AMQ 6209 in Detail

Understanding Hydac RF Filtration Systems

Understanding the BA 270 Course

Navigating the Realm of Business Communication