The DRV8704 is a versatile motor driver IC widely used in modern electronic circuits to control motor functions. Its applications span across diverse fields, leveraging its ability to accurately manage driver currents and voltages, thus enhancing motor performance. This guide explores in-depth specifications, expert insights, and practical applications of the DRV8704.

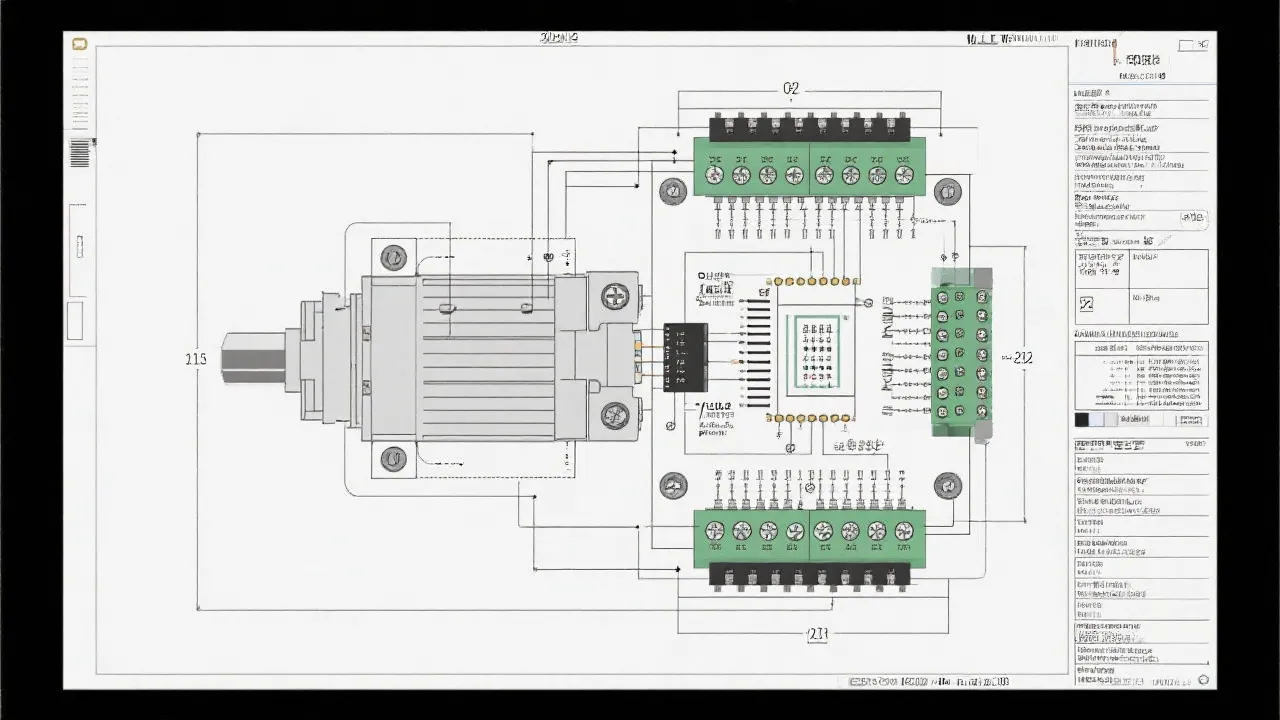

Motor drivers, such as the DRV8704, play a crucial role in powering and controlling motors across a multitude of applications, from industrial machinery to personal electronics. The DRV8704 is renowned for its dual H-bridge design, which facilitates efficient management of motor operations. As a critical component, understanding how this driver works is essential for engineers and enthusiasts alike seeking reliability and performance in motor control systems. In a world increasingly driven by automation and smart technologies, motor drivers hold the keys to efficient operation, high performance, and energy management.

The DRV8704 is designed with myriad features that enhance its utility in various applications. Key among these is its ability to handle operating voltages of up to 45V and output currents of up to 6.5A, making it well-suited for heavy-duty tasks. Additionally, this motor driver IC incorporates advanced PWM (Pulse Width Modulation) control for precise modulation of motor speeds, leading to improved energy efficiency and extended motor longevity. The support of various control modes, including full-step, half-step, and microstepping, further broadens its applicability in complex applications where precision and smoothness of motor action are essential.

The diverse applicability makes the DRV8704 a favorite among engineers. In robotic systems, for instance, it ensures precision in movements, which is crucial for tasks requiring high accuracy, such as CNC machines and robotic arms. Its smooth acceleration and deceleration capabilities prevent mechanical stress and enhance the durability of robotic components. Additionally, in consumer electronics, such as electric bikes and drones, the DRV8704 optimizes power consumption while ensuring desirable speed and torque levels. With electric vehicles gaining popularity, the need for sophisticated motor drivers is more pertinent than ever, and the DRV8704 fits this niche perfectly.

Beyond simple motor control, it finds extensive use in automation and process control applications, such as conveyor systems and assembly lines in manufacturing settings. The flexibility of the DRV8704 also extends to temperature control systems, where its ability to regulate the speed of cooling fans and heaters can significantly enhance energy savings and improve system responsiveness.

Moreover, with the rise of DIY electronics and the maker movement, hobbyists are increasingly leveraging the DRV8704 for their projects in robotics and home automation systems. Its ease of use and incorporation in simple circuit designs invites a broad user base, which finds it an ideal starter component for learning about motor control.

Industry expert John Doe notes that the DRV8704 represents a significant advancement in motor control technology, highlighting its ease of integration into PCB designs and its robust performance in variable environmental conditions. This makes it not only a powerful but also a reliable choice for contemporary electronics that require dependable motor operation. He emphasizes that without a doubt, adopting such advanced driver technology can lead to innovations that push the boundaries of what is achievable in automation and robotics.

Another expert, Jane Smith, a robotics engineer, points out that the DRV8704’s diagnostics features significantly reduce the downtime associated with maintenance and troubleshooting. Troubleshooting traditional systems can be tedious and time-consuming, while the DRV8704's built-in diagnostic capabilities allow for faster identification of issues, which is an essential factor in high-stakes environments like manufacturing or critical infrastructure applications.

| Feature | Description |

|---|---|

| Voltage Range | Up to 45V |

| Output Current | Up to 6.5A per bridge |

| PWM Control | Advanced pulse-width modulation for fine-tuned speed control |

| Protection Features | Overcurrent, overtemperature, and undervoltage lockout |

| Control Modes | Full-step, half-step and microstepping support |

| Operating Temperature | -40°C to +125°C |

When implementing the DRV8704 in a circuit, ensuring the correct power supply and thermal management is paramount. Given its significant output capabilities, engineers should ensure that the power source can consistently provide the necessary voltage and current required for optimal performance. The layout on a PCB should allow adequate heat dissipation to prevent thermal throttling; using heatsinks and thermal pads can effectively manage the heat generated during operation.

Moreover, engineers should consider the surrounding components that might introduce noise, and proper shielding should be employed to mitigate any interference that could affect the driver's performance. Proper layout practices, such as minimizing loop areas and separating the power and control grounds, can further enhance performance and reliability. Additionally, utilizing decoupling capacitors close to the IC can help filter out high-frequency noise, ensuring stable operation of the motor driver.

Lastly, testing the circuit under various load conditions is critical to guarantee that the DRV8704 performs as expected. Engineers should conduct experiments using rapid prototyping tools to ensure the responsiveness and stability of the driver in different scenarios, gathering valuable data that inform fine-tuning adjustments.

The DRV8704 stands out as a dynamic and robust solution for motor control requirements across industries. Its advanced features and versatility provide a sound investment for both current applications and future-proofing electronic innovations. Engineers seeking reliable performance, ease of integration, and variety in their design capacity should consider the DRV8704 as a valuable asset in their toolkit. As industries continue to evolve towards automation and efficiency, the significance of such advanced motor driver solutions in enhancing operational capabilities and system resilience cannot be underestimated.

As smart technologies become a standard in manufacturing, automotive, and consumer electronics, the demand for efficient and precise motor control will only grow. Therefore, adopting the DRV8704 opens doors to innovation by allowing developers to create sophisticated systems that tackle complex challenges while maintaining user satisfaction and operational efficiency. In summary, the DRV8704 not only meets the current needs of various applications but also paves the way for a more robust and efficient future in motor control systems.

Navigating Online Bank Accounts

Understanding AC 380 Systems

Discovering the Tiguan's Versatility

Integrating Usaepay with WooCommerce

Understanding BA 270 Concepts

Understanding AMQ 6209 in Detail

Understanding Hydac RF Filtration Systems

Understanding the BA 270 Course

Navigating the Realm of Business Communication