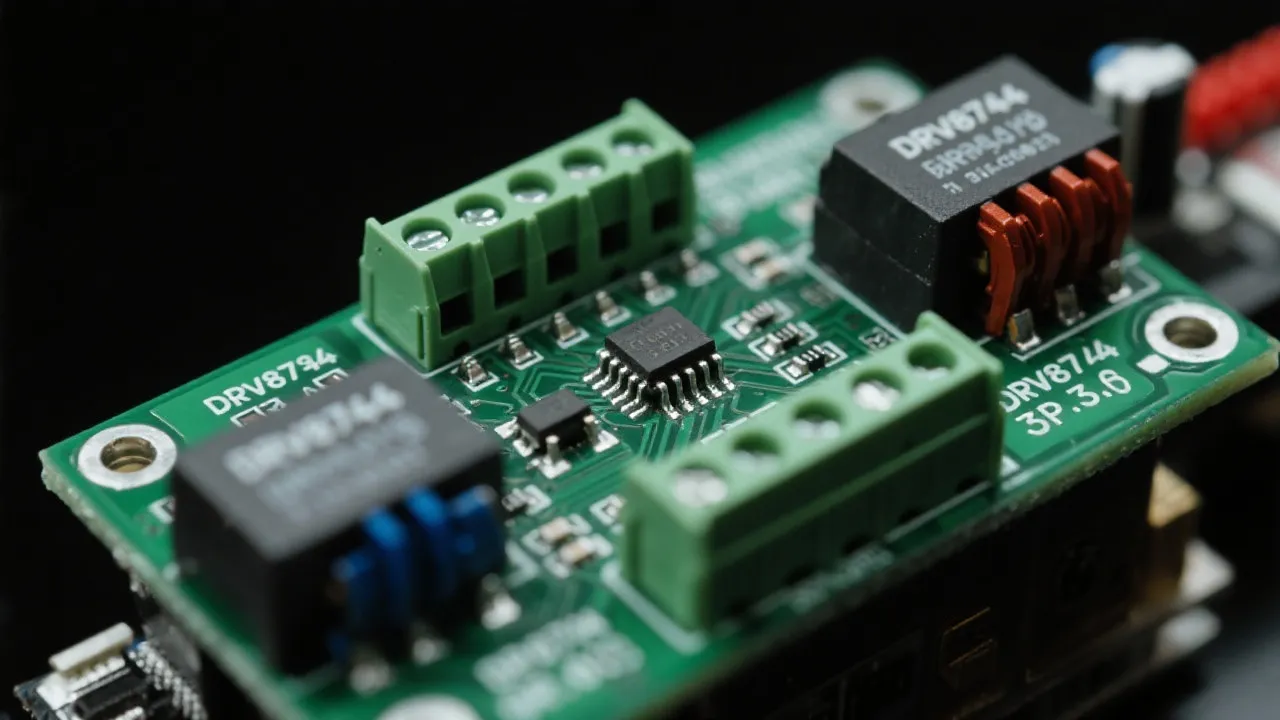

Introduction to the DRV8704 Motor Driver

The DRV8704, developed by Texas Instruments, is a highly efficient pulse-width modulation (PWM) motor driver that caters to a wide range of industrial applications. Its design prioritizes flexibility and performance, making it a popular choice for engineers and product developers. In this article, we will explore the DRV8704’s specifications, its applications, and essential factors to consider when selecting a motor driver, as well as delve deeper into its practical implications, operational characteristics, and comparisons with other motor drivers in the market.

Key Specifications and Features

The DRV8704 stands out in the realm of motor drivers due to its significant power and efficiency features:

- Voltage Range: Operates effectively in a voltage range of 6.5 to 45 volts, providing versatility for various setups. This range allows the DRV8704 to cater to both low-voltage applications and those requiring higher voltages, thus appealing to a diverse market.

- Current Control: Utilizes advanced PWM current regulation, allowing precise control over motor performance. This feature is crucial not only for performance tuning but also for energy efficiency, as it minimizes wasted power during operation.

- Protection Algorithms: Equipped with protections against overcurrent, short circuit, under-voltage lockout, and overtemperature, thereby substantially enhancing operational reliability and longevity. These features make the DRV8704 a heavily fortified choice, capable of withstanding fluctuating conditions and preventing potential failures in designs.

- Dual H-Bridge: The dual H-Bridge design allows for full-bridge configuration, facilitating the control of two separated motor loads simultaneously, enabling designs that require multi-motor synchronizations, such as in robotics or conveyor systems.

- Ease of Integration: The DRV8704 comes with a simple pinout design that eases the integration into existing systems and works well with common microcontrollers, enhancing its usability across projects of varying complexities.

Applications of the DRV8704

The DRV8704's adaptability makes it suitable for a wide array of applications, including:

- Industrial Robotics: Provides the necessary precision and power control required in industrial robotic arms and other automated systems. The ability to fine-tune motor responses can greatly improve the accuracy of tasks such as pick-and-place operations in manufacturing environments.

- Electric Vehicles: Ideal for managing the motor control functions found in electric scooters and bicycles, where efficient power management is crucial. This includes applications where battery life is a critical aspect, as the DRV8704’s efficiency helps prolong drive times.

- Home Appliances: Used in modern automated home appliances like vacuum cleaners and washing machines that require controlled motor speeds. The ability of the DRV8704 to handle varying loads and speed settings contributes to the performance and efficiency of these devices.

- Agricultural Equipment: In agricultural robotics, the driver controls motors that operate automation systems for tasks like planting, watering, or monitoring crops. This can include devices such as automated tractors that require high torque and precise motor control for efficient operation.

- Medical Devices: The DRV8704 can also be found in medical applications, such as in robotic surgery tools or in devices that assist with mobility. Here, reliability and precision are paramount, as they can directly impact patient safety and procedure outcomes.

FAQs

- What makes the DRV8704 efficient for industrial use?

The DRV8704’s efficiency stems from its ability to manage high power loads effectively, its comprehensive protection features, and its wide operating range, making it suitable for demanding industrial environments. Its design effectively balances power usage against performance, resulting in minimal energy costs over time, which is a key consideration for any business.

- Can the DRV8704 be used for both brushed and brushless motors?

While it is typically used for brushed DC motors, its configuration can support a variety of motor types through advanced design capabilities. It's important for the user to carefully analyze the specifications and apply additional features or circuits if they aim to use it with brushless DC motors, such as electronic commutation methodologies.

- How does the DRV8704 improve motor lifespan?

By employing precise current regulation, responsive to load changes, and protective algorithms to prevent damage from overheating or electrical faults, the DRV8704 extends the operational lifespan of motors. This translates into fewer maintenance cycles and lower replacement costs over the lifespan of the equipment it powers.

Choosing the Right Motor Driver

Selecting an appropriate motor driver involves consideration of several critical factors parallel to those embodied by the DRV8704:

- Voltage and Current Requirements: Ensure that the driver supports the voltage and current specifications of your motor. Every motor has a specified range it operates within, and choosing a driver like the DRV8704 which spans a broad voltage range adds flexibility, allowing you to scale your projects over time without needing to replace the motor driver as the application evolves.

- Thermal Management: Consider the driver’s capacity for heat dissipation, crucial for maintaining performance and avoiding overheating. Designers should account for the thermal characteristics of the application environment to ensure that the driver can maintain operational integrity, potentially integrating heatsinks or active cooling in high-load scenarios.

- Control Features: Determine if you need advanced features like microstepping or PWM control, as offered by the DRV8704. The ability to finely control stepper motors can significantly impact performance in applications that require high precision, thereby affecting end-user experiences and operational efficiency.

- Ease of Use and Compatibility: It’s essential to ensure that the chosen driver integrates easily with your existing hardware, including microcontrollers and power supplies. Review the DRV8704's compatibility with popular microcontrollers and development platforms, which simplifies prototyping and testing phases.

- Cost Versus Performance: Finally, factor in the cost relative to the features offered. The DRV8704, while potentially higher in cost than more basic drivers, may provide superior longevity and reliability that justifies the expense through reduced operational costs across its lifetime.

Comparing the DRV8704 with Other Motor Drivers

When evaluating the DRV8704, it is beneficial to compare its performance characteristics and features against other motor drivers in the industry. For instance, against competitors like the L298N or the TB6600, the DRV8704 exhibits superior efficiency due to its advanced PWM control and integrated protections.

The L298N, a well-known dual H-Bridge motor driver, is a go-to standard in many applications, but it suffers from considerable heat generation and lower efficiency ratings, especially in high-load conditions. In contrast, the DRV8704's design allows for cooler operation and better handling of high currents without the need for excessive heatsinking.

The TB6600, preferred for use in CNC applications, offers great torque and is designed for stepper motors. However, it may lack the versatility of operation for a wide array of motor types as seen with the DRV8704, which allows for more flexible designs in varying projects whether it includes DC brushed motors or other configurations.

Ultimately, choices will depend on specific application requirements, weighing factors like load demands, thermal management capacity, feature sets, and budget considerations.

Best Practices for Using the DRV8704 Motor Driver

Implementing the DRV8704 effectively in your designs requires adherence to several best practices:

- Supply Decoupling: Always utilize decoupling capacitors close to the power pins of the DRV8704 to counteract voltage spikes and ensure stable operation. A combination of large bulk capacitors and smaller ceramic capacitors will offer a spectrum of filtering across frequencies.

- Current Sensing: If your application permits, utilize the current sense output to monitor performance and dynamically adjust parameters. This not only assists in managing load conditions but can also trigger alerts for overcurrent situations.

- Thermal Considerations: Monitor the thermal performance during operation. Employing thermal pads or heatsinks enhances the thermal dissipation and may also allow finer control over motor performance in critical applications.

- Firmware Development: Include robust control algorithms in your firmware to maximize the capabilities of the DRV8704. Implementing features such as closed-loop motor control can significantly improve performance in dynamic applications, enhancing responsiveness and adaptability.

- Testing under Load: Always test the system under conditions that closely replicate the operational environment to ensure that the performance remains consistent and that thermal limits are adhered to.

Conclusion

The DRV8704 from Texas Instruments exemplifies the blend of versatility and reliability required for contemporary motor control applications. Its sophisticated design aligns with the needs of industrial, transportation, and consumer markets, providing a range of features that cater to the demands of modern devices. By understanding its capabilities and aligning them with your application’s requirements, you can harness the full potential of the DRV8704 motor driver to enhance both performance and efficiency in your projects. As motor control technology continues to evolve, drivers like the DRV8704 set a standard that offers not just operational benefits but also opens avenues for innovation in various industries, making it an essential consideration for future developments.