The DRV8704 is an advanced motor driver designed to enhance the capabilities of brushless DC and stepper motors. Offering a sleek integration of hardware and software control, it is a vital component for industries aiming to optimize motor performance. This article will delve into the functionalities of the DRV8704, providing insights on its benefits and applications in modern-day technology.

The DRV8704 by Texas Instruments stands as a pinnacle of modern motor control technology. It is designed to accommodate the intricate demands of high-performance brushless DC (BLDC) and stepper motors. By understanding the DRV8704’s functionalities and applications, industries can seamlessly integrate it within various technological frameworks for enhanced efficiency and operation. This introduction sets the stage for a deeper exploration into the specifications, benefits, and diverse applications of this sophisticated motor driver.

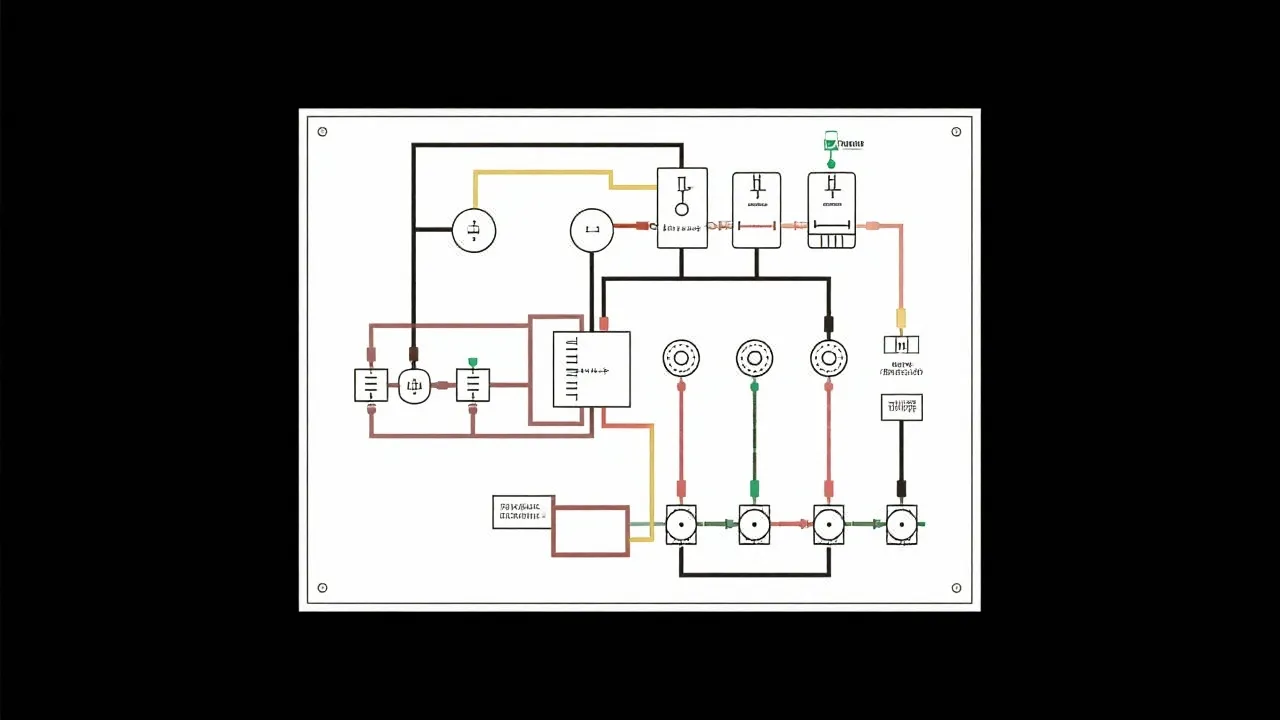

The DRV8704 motor driver offers a combination of hardware and software features that make it indispensable for precision motor control. Notably, it includes configurable current regulation, a microprocessor interface, and the ability to support multiple motor configurations. With its wide supply voltage range and robust design, the DRV8704 ensures reliable operation under diverse conditions. This section delves into the individual features, exploring how they contribute to the performance and flexibility of the driver.

| Specification | Details |

|---|---|

| Supply Voltage | 6.5V to 45V |

| Output Current | Up to 8A |

| Operating Temperature | -40°C to 150°C |

| Interface | SPI for communication |

| Motor Types Supported | BLDC and Stepper Motors |

| Fault Conditions | Overcurrent and overtemperature protection |

| Control Modes | Six-step control, microstepping for stepper motors |

| Dimensions | 4 mm x 4 mm QFN package |

The DRV8704 excels in applications requiring precise motor control, such as automated industrial machinery, robotics, and precision instrumentation. The driver’s ability to sustain high current outputs with minimal thermal issues makes it ideal for these demanding environments. Furthermore, the easy integration with microprocessors enables tailored performance tuning, thus optimizing energy consumption and extending motor life. This section outlines some specific applications in different industries.

In industrial settings, the need for reliable and efficient motor control is paramount. The DRV8704 is perfect for driving conveyor belts, automated assembly lines, and various types of actuators. Its capability to handle high currents allows it to power heavy-duty motors that are commonplace in such applications. With precise control over the motor parameters, manufacturers can ensure consistent production rates and improved safety measures in machinery. The energy-saving features also lead to substantial cost reductions in factory operations over time.

For robotics, both in leisure and competitive fields, precision is everything. The DRV8704 not only enables precise positioning through its configurable current and voltage but also provides smooth motion profiles which are critical for achieving delicate tasks. For example, robotic arms used in surgical applications can benefit significantly from the driver’s ability to execute fine movements, increasing the overall effectiveness and safety of procedures. Additionally, the communication capabilities with microcontrollers facilitate real-time adjustments based on feedback from sensors, enhancing the robot's adaptability to changing environments.

In the realm of medical devices, reliability is non-negotiable. The DRV8704's robust design, combined with its thermal management capabilities, allows it to be utilized in a variety of medical equipment, such as infusion pumps and diagnostic imaging systems. With the ability to precisely regulate motor outputs, it ensures that devices operate within specifications, which is critical for patient safety. Moreover, its compact size helps in the design of portable medical devices where space is restricted.

Consumer electronics also leverage the DRV8704’s features to improve performance. From drones requiring effective propulsion systems to robotic vacuum cleaners needing efficient navigation and operation, the motor driver serves versatile roles across many devices. Its capability to easily interface with processors allows for the integration of sophisticated control algorithms that can enhance user experience through better responsiveness and lower power consumption.

Compared to other motor drivers in its class, the DRV8704 offers an unparalleled combination of flexibility and power. Its configurable settings allow engineers to customize parameters like current limits and voltage thresholds, effectively catering to the unique requirements of each application. This versatility ultimately translates into lower overall system costs and a reduced footprint. Examining the versatility of the DRV8704 in context with its potential competitors highlights its distinct advantages.

When benchmarked against competitors, the DRV8704 consistently excels in areas such as thermal performance and configurability. Many alternatives in the market may offer good performance metrics, but they often lack the extensive features found in the DRV8704, such as integrated thermal shutdown and detailed configuration flexibility. For instance, while a competing driver may support only a fixed current limit, the DRV8704 allows designers to manually set thresholds as required for their specific application, whether it be robotics or industrial automation.

The compact design of the DRV8704 also reduces the PCB space required substantially when compared to older or less advanced motor drivers. This is a crucial advantage in systems where every square millimeter counts, such as in handheld devices or compact industrial equipment. The result is a streamlined design process and potentially lower manufacturing costs due to reduced material usage.

Customization extends beyond simple current limits. With the DRV8704, engineers can tailor the driver’s response to fit unique application needs. For example, in high-precision positioning applications, one can configure the step modes for stepper motors to improve resolution and minimize vibration. Such tuning capabilities are indispensable in both research and applied engineering fields where fine motor control is paramount.

The DRV8704 is designed with robust components that withstand harsh industrial environments, offering reliability and good durability. Its ability to manage heat efficiently ensures that it can operate continuously under heavy loads without failure, thus maintaining productivity in industrial processes.

Yes, its user-friendly interface and adaptable configurations make it suitable for both professional and hobbyist applications. Enthusiasts can easily incorporate the DRV8704 into their projects, from 3D printers to robot cars, leveraging its flexibility and performance for experimentation and innovation.

The SPI interface allows for seamless communication with microprocessors, facilitating precise control and real-time feedback adjustments. The high data transfer speeds available through SPI ensure that the driver can quickly respond to changes in control inputs, thereby enhancing system performance and reliability.

The driver is primarily compatible with brushless DC (BLDC) and various stepper motors. This versatility allows it to be used in a wide range of applications, allowing for direct control of motor functions without needing extensive interface protocols.

The DRV8704 incorporates thermal shutdown features that protect both the driver and the connected motor from overheating situations. Furthermore, its design facilitates effective heat dissipation, which is essential in maintaining performance during extended operations at high currents.

The adjustable current limit allows designers to fine-tune the power supplied to the motor based on specific operational parameters. This precision not only enhances the efficiency of operation but extends the lifespan of both the motor and the driver by preventing excessive current draw under load conditions.

By integrating the DRV8704, industries can achieve sophisticated motor control solutions that enhance overall system performance. The combination of its adaptability and reliability makes it a key component in advancing technological capacities. Whether for large-scale industrial ventures or intricate robotics projects, the DRV8704 continues to set a benchmark in motor driver technology. Looking ahead, as automation and smart applications become increasingly integral to both industry and daily life, the importance of advanced motor drivers like the DRV8704 will grow, leading the charge for innovation, efficiency, and performance in a multitude of fields. Its ongoing evolution showcases the power of engineering advancements that cater to the ever-expanding demands of modern technology.

Navigating Online Bank Accounts

Understanding AC 380 Systems

Discovering the Tiguan's Versatility

Integrating Usaepay with WooCommerce

Understanding BA 270 Concepts

Understanding AMQ 6209 in Detail

Understanding Hydac RF Filtration Systems

Understanding the BA 270 Course

Navigating the Realm of Business Communication