The DRV8704 is a comprehensive motor driver solution designed for industrial applications. As a key component known for its robust performance, it is integral in managing the operation of various motor systems efficiently. With a focus on its design, capabilities, and potential applications, this guide explores its technical specifications and integration processes within diverse environments.

As modern technology increasingly leans on automation and precise control systems, the DRV8704 motor driver emerges as a key player in this dynamic field. Known for its high efficiency and versatile operation, the DRV8704 is specifically engineered to manage a variety of motor types, including Stepper and Brushed DC motors. Ideal for industrial systems, its design exemplifies a commitment to optimal motor performance and reliability. This device, utilizing cutting-edge technology, ensures a seamless integration into various applications, significantly enhancing their functionality and efficiency. The trend towards automation and intelligent machines in sectors such as manufacturing, robotics, and transportation makes the DRV8704 more relevant than ever.

The DRV8704 is a H-bridge motor driver designed to control motion dynamics with precision. It supports a wide input voltage range, generally from 6.5V to 45V, making it suitable for different power supply conditions. Furthermore, the DRV8704 features current regulation settings that enhance motor lifespan and reduce thermal stress. This sophisticated driver can handle high current applications, typically up to 12A, and offers microstepping capabilities which are critical for precision tasks. In addition, the ability to seamlessly switch between different control modes allows engineers and developers to adapt the DRV8704 to their specific operational needs.

Notably, the internal architecture of the DRV8704 incorporates advanced feedback mechanisms which monitor the status of the motors, ensuring that parameters such as current output and temperature remain within safe operational limits. This built-in intelligence contributes to a significant increase in performance efficiency while simultaneously lowering the risks of motor failure.

One of the noteworthy applications of the DRV8704 is in robotic systems, where accuracy and response time are crucial. Its ability to support dual H-bridges simplifies the design and boosts the efficiency of robotic arms and automated guided vehicles (AGVs). In the realm of CNC machinery, the DRV8704's microstepping capabilities allow for smoother transitions and finer control, thereby improving the quality of finishing in parts manufacturing. Furthermore, the integration of DRV8704 into 3D printers has transformed printing technology, enabling higher precision and faster print times.

Beyond traditional automation, the DRV8704 is also employed in automotive applications, enhancing features such as electronic power steering and automated seat adjustments, where reliability and efficiency are paramount. Additionally, its compact design makes it a favored choice in portable devices, offering both robust performance and a lightweight footprint which is essential in mobile applications. In mechatronics, such as precision tools, the DRV8704 allows for intricate control that enables the creation of more complex and functional designs.

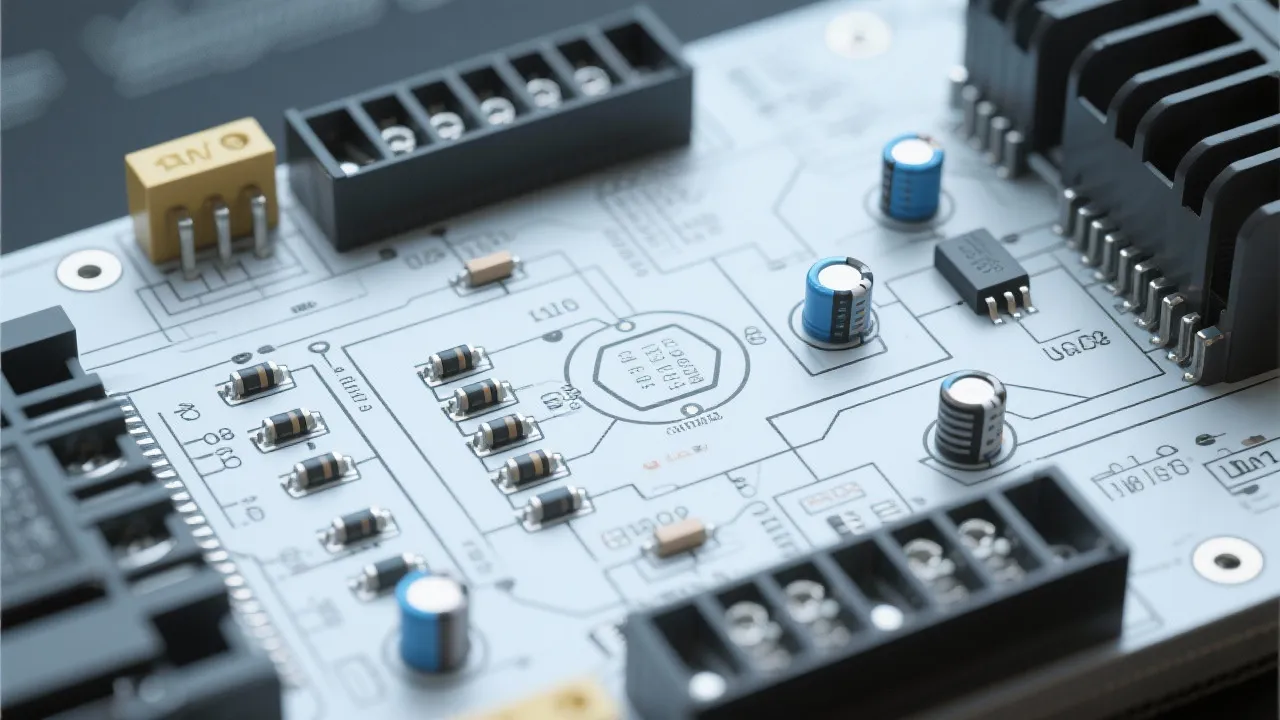

The process of integrating the DRV8704 into your system involves several key steps. Initially, careful attention must be paid to the PCB layout. Keeping power traces short and balanced helps minimize electromagnetic interference. Furthermore, ensuring a proper ground plane can significantly enhance the noise immunity of your design, which is critical for maintaining signal integrity.

Additionally, implementing adequate decoupling capacitors is imperative to mitigate voltage spikes and ensure stable operation. These should be placed as close to the power pins of the DRV8704 as possible to maximize their effectiveness. Configuration of the driver through its SPI interface allows for precise control over its features, including setting the required current levels for operation. The register-based control offers a high degree of customization that can be tailored to specific application needs.

Moreover, considering thermal management is vital during the implementation phase. Factors such as ambient temperature, airflow, and the thermal properties of surrounding materials play a crucial role in the operational efficiency of the DRV8704. Regular thermal analysis can help in designing a system that supports long-term reliability. Implementing heatsinks, thermal pads, or even active cooling methods will help in maintaining safe operation temperatures.

| Feature | Specification |

|---|---|

| Operating voltage range | 6.5V - 45V |

| Output current capacity | Up to 12A |

| Microstepping capability | Yes |

| Communication interface | SPI |

| Protection features | Overcurrent, overtemperature |

| Driver type | H-Bridge |

| Control modes | Full Step, Half Step, Microstepping |

Utilizing the DRV8704 in your system offers numerous benefits. Its ability to handle high current loads with integrated protection mechanisms helps in building robust systems that are less prone to damage from electrical faults. Additionally, the flexibility of its adjustable settings and operational modes make it a valuable asset across diverse applications. For instance, the driver’s ability to function in microstepping mode enhances the smoothness of motor operation, which is invaluable in applications requiring precise motion control.

However, it is crucial to acknowledge the limitations that stem from thermal management issues in higher ambient temperature scenarios. Implementing effective heat dissipation strategies, such as heatsinks or fans, is often necessary to maintain optimal performance. The operational limits of the DRV8704 can reduce under high-stress conditions, necessitating careful planning and consideration during design and implementation phases.

Furthermore, initial setup and calibration may require a thorough understanding of the driver’s configuration options. Engineers must invest time to familiarize themselves with the SPI communication protocols and programming parameters to ensure optimal performance. While this can be a minor obstacle, the complexity can be mitigated with comprehensive documentation and direct support from the manufacturer.

The DRV8704 is versatile enough to control both Brushed DC and Stepper motors, providing flexibility in a wide range of applications. This capability not only simplifies the design process but also enables developers to prototype and modify their systems without extensive rework.

This motor driver includes several protection features such as overcurrent and overtemperature protection to safeguard against operational hazards. In instances where the motor draws excessive current, the DRV8704 is equipped to automatically adjust its output or disable drive functions to prevent hardware damage.

Yes, through its microstepping and current regulation features, the DRV8704 allows for precise adjustments in speed and torque. Developers can optimize these parameters for their specific applications, ensuring that the motor operates within its ideal performance range.

The DRV8704 is ideally suited for applications that require high precision and reliability. Common use cases include robotics, CNC machinery, 3D printing devices, and automotive systems. Its flexibility allows it to adapt to various engineering challenges, making it a go-to driver for many design engineers.

When utilizing the DRV8704, it is essential to ensure that your power supply meets the voltage and current specifications necessary for your application. Moreover, filtering and decoupling should be implemented to minimize noise and electrical disturbances, which could affect performance and reliability.

Incorporating the DRV8704 into your motor systems offers a combination of flexibility, power, and protection that is ideal for modern industrial applications. Whether optimizing for robotics, CNC machines, or other automation systems, understanding its capabilities and limitations ensures that you can harness its full potential for enhanced device performance. Its advanced features, combined with extensive configurability, make it an essential component in cutting-edge motor control solutions. As the demand for increasingly sophisticated and efficient motor systems grows, the DRV8704 stands out as a reliable choice that can significantly contribute to innovation and efficiency across various fields.

The performance of the DRV8704 is further distinguished by its innovative power management techniques. By utilizing techniques such as PWM (Pulse Width Modulation) control, the driver efficiently manages power levels while maintaining performance integrity across various motor speeds and torques. This results in reduced energy consumption and improved overall efficiency, essential for battery-operated applications where power conservation is critical.

As industries prioritize sustainability, the environmental impact of motor drivers, including the DRV8704, is becoming increasingly important. The efficiency and thermal management of the DRV8704 contribute to lower energy consumption, which is beneficial for reducing greenhouse gas emissions. Manufacturers that incorporate the DRV8704 into their processes may improve their sustainability profiles, aligning with global efforts to minimize environmental footprints. Furthermore, as tech industries advance towards greener technologies, the importance of selecting motor drivers that contribute to sustainable practices becomes clear.

Looking ahead, trends in motor driver technology are predominantly centered around increased efficiency, miniaturization, and enhanced connectivity. The demand for higher power densities in compact form factors drives the continuous improvement of motor drivers like the DRV8704. Future iterations may include greater integration of digital control systems, allowing for real-time adjustments and advanced motor diagnostics, thus enhancing both performance and usability.

The rise of IoT (Internet of Things) creates further opportunities for innovation as motor drivers begin incorporating more advanced communication protocols. Integration with smart systems enables automated diagnostics and predictive maintenance, providing significant advantages in industrial settings. The evolution of artificial intelligence and machine learning may also lead to adaptive motor control strategies, improving the performance of motors across various applications.

Incorporating the DRV8704 into your motor systems not only brings immediate operational benefits but also positions developers and engineers at the forefront of technological innovation. Its outstanding flexibility, high performance, and robust protective features facilitate advancements across various applications. As industry demands evolve, motor drivers are becoming increasingly vital to achieving operational excellence. With the DRV8704, businesses can ensure they remain competitive, efficient, and ready to respond to the challenges of a rapidly changing technological landscape.

Navigating Online Bank Accounts

Understanding AC 380 Systems

Discovering the Tiguan's Versatility

Integrating Usaepay with WooCommerce

Understanding BA 270 Concepts

Understanding AMQ 6209 in Detail

Understanding Hydac RF Filtration Systems

Understanding the BA 270 Course

Navigating the Realm of Business Communication