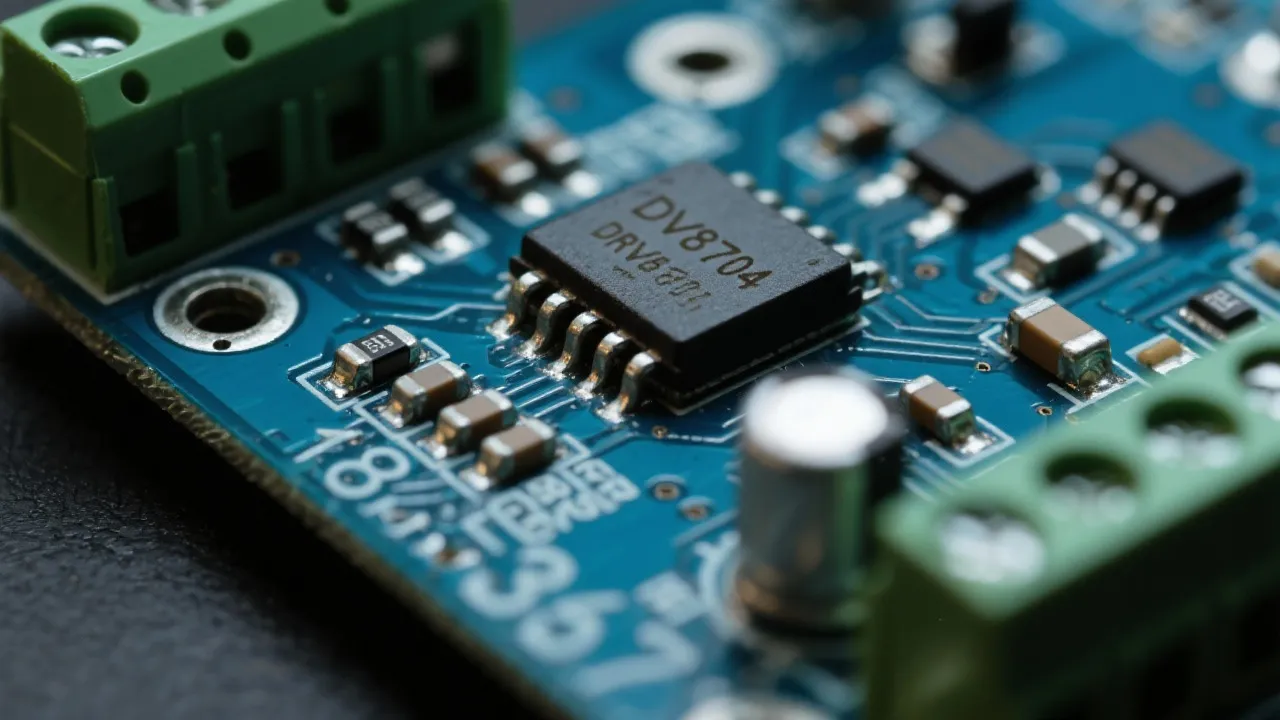

The DRV8704 is a robust motor driver designed to enhance efficiency in managing motor operations. This article explores its key features, applications, and benefits, catering to audiences seeking reliable motor control solutions. As an industry-standard component, its utilization spans numerous sectors, delivering precise control over various motor types, thereby optimizing performance and power consumption in numerous devices.

The DRV8704 motor driver is a flexible and powerful integrated circuit that aids in the control of motor mechanisms across various applications. This motor driver offers an impressive array of features that make it especially valuable in industrial processes requiring precise motor control. Whether it is for controlling the speed of a fan, the position of a robotic arm, or the operation of automated conveyor belts, the DRV8704 provides the necessary functionalities to maintain optimal performance. The DRV8704 is commonly employed in devices where efficiency and reliability are paramount, ensuring motor management is both seamless and effective.

With the exponential growth of automation and robotics in recent years, the demand for efficient and reliable motor controllers has surged. The DRV8704 meets this demand head-on, offering capabilities that not only support a variety of motor types but also include robust control features. As industries continually seek improvements in their operational efficiencies, the DRV8704 motor controller stands as a leading solution in modern motor control technology.

The DRV8704 is distinguished by its input control, which includes a PWM (Pulse Width Modulation) interface, allowing for easy integration into various control systems. Through PWM, the device can adjust the voltage and current flowing to the motor, making it possible to control speed with remarkable accuracy. The unit supports up to 45 volts operation with peak currents of 10.8A, thus accommodating a wide range of motor types and applications, from small hobbyist projects to large industrial machines.

Additional notable features include:

Overall, the DRV8704 represents a comprehensive solution that not only meets the basic requirements of motor control but also anticipates user needs for efficiency, precision, and reliability.

Due to its versatile nature, the DRV8704 can be found in several industrial and consumer applications. In automation, it drives motors responsible for positioning and transfer tasks. Its role can range from managing automated assembly lines to controlling material handling equipment with precision and speed. Furthermore, its compatibility with different motor types makes it suitable for use in robotics, where precision and power efficiency are critical. Robots in warehousing and logistics, for example, rely on such controllers to operate their robotic arms and navigate their paths accurately.

Automotive applications also benefit from its power management capabilities, promoting enhanced performance and reduced power consumption in vehicles. Electric vehicles (EVs), which require sophisticated motor control solutions to balance performance with battery life, often utilize the DRV8704 for driving the various motors involved, from wheel drives to auxiliary systems like ventilation and windshield wipers.

Additional applications of the DRV8704 include:

The DRV8704 motor controller offers numerous advantages that are particularly beneficial in today's competitive industrial landscape. One significant advantage is its improved energy efficiency, which can lead to substantial reductions in operational costs and enhanced environmental sustainability. By effectively managing power consumption through its advanced current regulation and PWM functionalities, it allows businesses to reduce their carbon footprint significantly while maintaining performance.

Furthermore, its robust diagnostics offer real-time insights into motor operations, effectively enabling proactive maintenance strategies that minimize downtime and extend equipment life. This characteristic is invaluable as companies strive to maximize productivity and minimize disruption in their operations. With its comprehensive control suite, engineers can implement tailored motor solutions that meet specific project needs, providing a meaningful competitive edge.

Other benefits of the DRV8704 encompass:

Employing the DRV8704 requires thoughtful consideration of your specific application needs. Key implementation requirements include:

| Requirement | Description |

|---|---|

| Voltage Availability | The DRV8704 supports up to 45V, necessitating a power supply within this range to ensure proper functionality and safety. |

| Motor Type | Applicable to both brushed and brushless DC motors, allowing for varied application deployment and providing designers with flexibility. |

| Environment | Automotive, industrial, and robotics applications are typical use cases, requiring consideration of operating conditions such as temperature fluctuations and vibration. |

| Cooling Considerations | In high-power applications, adequate thermal management is essential. Engineers must design appropriate heat dissipation mechanisms to avoid overheating. |

| Control Interface | Understanding and preparing the system for PWM input is vital for successful integration and expected performance. |

These considerations ensure that the DRV8704 operates efficiently within its intended parameters and can deliver optimal performance throughout its lifecycle. It is essential that engineers conducting implementations conduct thorough evaluations of these aspects before proceeding with integration.

When integrating the DRV8704, professionals recommend focusing on power handling capabilities and thermal considerations. Its robust design accommodates high-power applications, but it's crucial to ensure adequate cooling to maintain performance stability. The integration of heat sinks and fans may be necessary in high-load scenarios to mitigate potential overheating.

The microstepping feature provides remarkable precision; however, optimally leveraging this requires familiarity with both the motor being controlled and the controller's interface functionalities. Proper tuning of the microstepping settings — including step mode selection and current settings — is essential to achieve desired motor behavior. Engineers are encouraged to utilize diagnostic protocols that the DRV8704 supports to monitor performance during testing phases and adjust parameters accordingly.

Additionally, consideration of the motor characteristics — such as inductance and resistance — plays a vital role in the effective use of the DRV8704. This knowledge enhances the ability to establish suitable control parameters and ensure that motor operation aligns with project demands. In summary, while the DRV8704 is designed to facilitate effective motor control, success is reliant upon thoughtful integration and a nuanced understanding of both the driver and the motors it will control.

In conclusion, the DRV8704 motor controller stands as a pillar of modern motor control technology, offering unmatched flexibility and reliability. Its wide range of applications and features make it a compelling choice for designers and engineers aiming to enhance performance and efficiency in their motor-driven solutions. By considering factors like voltage supply, motor compatibility, and proper thermal management, users can integrate the DRV8704 for maximum benefit, paving the way for innovation across industries.

As automation continues to evolve and diversify across sectors, the role of capable motor controllers like the DRV8704 is becoming increasingly essential. Its ability to adjust to various operational demands assures its place as a fundamental component in the development of next-generation automation technologies. With the potential to optimize efficiency, performance, and reliability in motor control tasks, the DRV8704 reinforces its importance in contemporary engineering applications.

Companies adopting the DRV8704 will not only benefit from its immediate advantages but will also position themselves proactively in an ever-competitive market, where the efficiency and reliability of their automation solutions can significantly impact their overall success. With the DRV8704, engineers have the tools necessary to forge ahead into the future of automation, ensuring their projects are not only feasible but also primed for exceptional performance and long-term sustainability.

Navigating Online Bank Accounts

Understanding AC 380 Systems

Discovering the Tiguan's Versatility

Integrating Usaepay with WooCommerce

Understanding BA 270 Concepts

Understanding AMQ 6209 in Detail

Understanding Hydac RF Filtration Systems

Understanding the BA 270 Course

Navigating the Realm of Business Communication