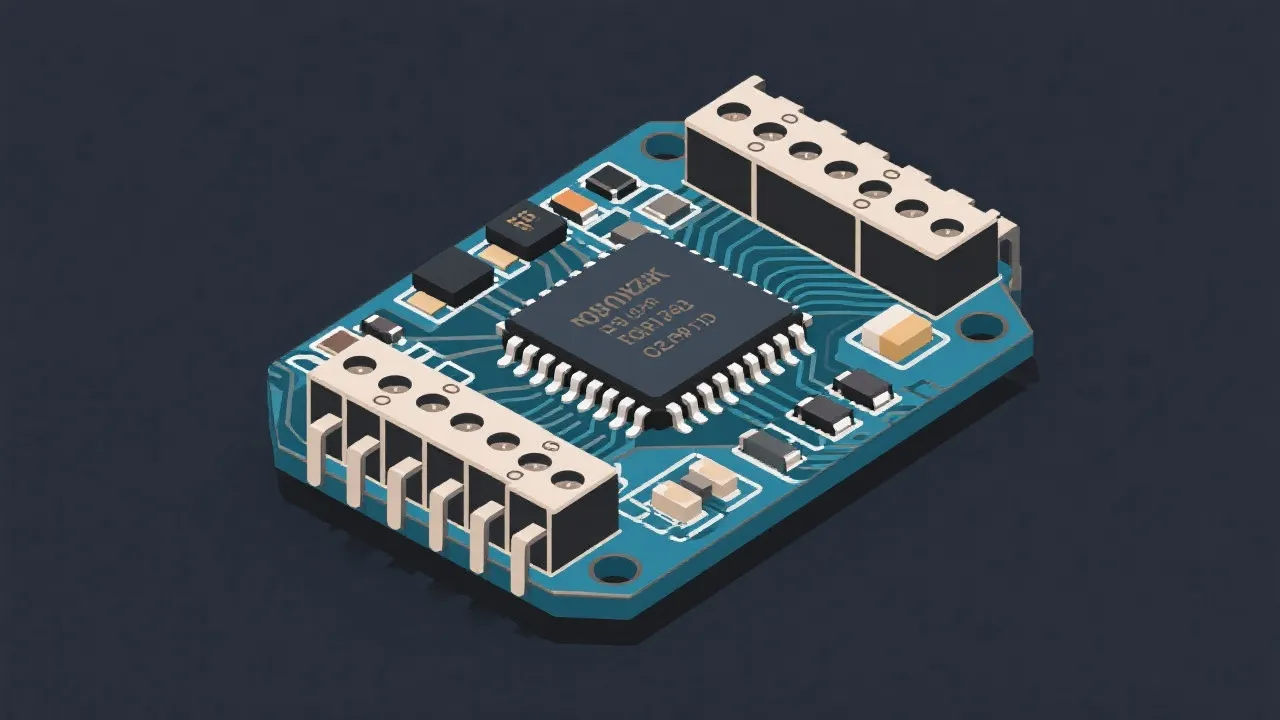

The DRV8704 is a versatile motor driver chip known for its robust performance in motor control applications. Designed to handle various requirements, this chip helps in precise motor driving tasks, making it ideal for engineers and technicians in industrial systems. Its adaptability and efficiency make it a preferred choice in automation and robotics sectors.

The DRV8704 motor driver chip is a critical component in the field of motion control, offering precise and efficient solutions for driving motors in a wide range of applications. This chip, renowned for its reliability and performance, is pivotal for engineers tasked with designing systems that require meticulous motor management and control. As the demand for efficient motor drivers rises, the DRV8704 has established itself as a preferred choice for many industrial and consumer applications.

With the ongoing advancement in technology, the need for complex motor control techniques has become essential, particularly in automated processes and robotics. The DRV8704 not only accommodates these requirements but also enhances the overall performance of systems relying on motor functionality. Understanding how the DRV8704 operates and its benefits positions engineers to leverage its capabilities fully.

This introduction sets the stage for a deeper exploration of the features, applications, and advantages of the DRV8704 motor driver, which is designed to meet the evolving demands of today's high-tech environment.

The DRV8704 is packed with features that make it a top choice for motor control applications:

The DRV8704's adaptability makes it suitable across multiple sectors, including:

The integration of the DRV8704 into motor control systems presents numerous benefits, such as:

From an expert perspective, the DRV8704 remains at the forefront of motor control technology. Its robust design and operational flexibility serve as a testament to its widespread adoption in high-demand environments. Industry professionals praise the DRV8704 for its adaptability to meet various operational requirements while maintaining high reliability standards.

The shift towards automation in industries such as manufacturing and pharmaceuticals has fueled the demand for advanced motor control solutions. As companies strive to enhance productivity and efficiency, the DRV8704's features become increasingly advantageous. Furthermore, the trend towards green technologies and energy-efficient solutions amplifies the importance of employing motor drivers that reduce energy consumption, further positioning the DRV8704 as a leader in the market.

Additionally, the growing venture into IoT (Internet of Things) applications has opened new doors for driver technology. The DRV8704 is often integrated into smart devices, which rely on efficient motor control to achieve seamless user experiences. This trend emphasizes the chip's essential role in enabling the functionalities of modern, connected devices.

Emerging trends also indicate a rising interest in miniature and portable devices that require highly efficient power management. The DRV8704's capabilities and compact design make it a go-to solution for engineers looking to innovate within strict space and power constraints.

While the DRV8704 offers numerous benefits, engineers must also consider specific challenges when implementing this motor driver. Some of the potential challenges include:

Q: What is the maximum voltage the DRV8704 can handle?

A: The DRV8704 can handle a voltage range up to a specified maximum which is typically detailed in its datasheet. Generally, it supports voltages up to 60V, making it suitable for high-performance applications.

Q: How does the DRV8704 enhance motor efficiency?

A: By utilizing adaptive current regulation techniques, the DRV8704 minimizes power losses, thus enhancing overall efficiency. This is achieved through its advanced control algorithms that adapt to varying load conditions.

Q: Can the DRV8704 be used in harsh environmental conditions?

A: The DRV8704's design includes various protective features making it suitable for many demanding applications, though specific environmental conditions should be referenced in its guidelines. It is essential to evaluate the application's specific requirements for optimal performance under those conditions.

Q: What is the expected lifespan of the DRV8704 motor driver?

A: The lifespan of the DRV8704 typically depends on the operating conditions and thermal management. With proper usage and adherence to the recommended guidelines, the DRV8704 can deliver long-term reliability and performance.

Q: How can I customize the performance settings of the DRV8704?

A: The DRV8704 allows users to adjust output current modulation settings and other configuration parameters via its control interface. This flexibility enables engineers to tailor the motor control behavior to meet specific application demands effectively.

The DRV8704 motor driver, with its array of features and applications, is an indispensable tool in the realm of motion control systems. Its ability to provide precise, efficient management across diverse applications places it at the helm for engineers and designers seeking a reliable motor control solution. Embracing the DRV8704 means opting for a product that delivers efficiency, durability, and versatility in equal measure. As industries continue to evolve and embrace automation, the role of the DRV8704 will only grow in importance, aiding in the development of innovative solutions that push the boundaries of what is possible in motor control technology.

Ultimately, the continued investment in research and development surrounding motor driver technology indicates that products like the DRV8704 will undergo further enhancements, keeping pace with technological advancements and contributing to the improvement of overall system performance in an increasingly automated world. Understanding the DRV8704 and its capabilities allows engineers to stay at the forefront of their fields and leverage these advancements for greater efficiency and innovation.

Navigating Online Bank Accounts

Understanding AC 380 Systems

Discovering the Tiguan's Versatility

Integrating Usaepay with WooCommerce

Understanding BA 270 Concepts

Understanding AMQ 6209 in Detail

Understanding Hydac RF Filtration Systems

Understanding the BA 270 Course

Navigating the Realm of Business Communication