The DRV8704 is a highly efficient motor driver widely used in applications requiring precision control. Renowned for its robustness, it supports complex motor management tasks in industrial and consumer electronics. This article delves into the features, applications, and technical specifications of the DRV8704, offering a detailed analysis for engineers and hobbyists alike.

The DRV8704 is an advanced motor driver designed for industrial and consumer applications that demand precision and versatility. Its introduction has enhanced motor control systems by providing improved efficiency and reduced form factor, coupled with features that cater to modern engineering needs. Understanding its capabilities is essential for any professional engaged in automation and electronics. As industries increasingly pivot towards automation and smart technology solutions, components like the DRV8704 play a crucial role in bridging the gap between simple mechanical systems and sophisticated automated processes, ensuring that devices operate with both efficiency and reliability.

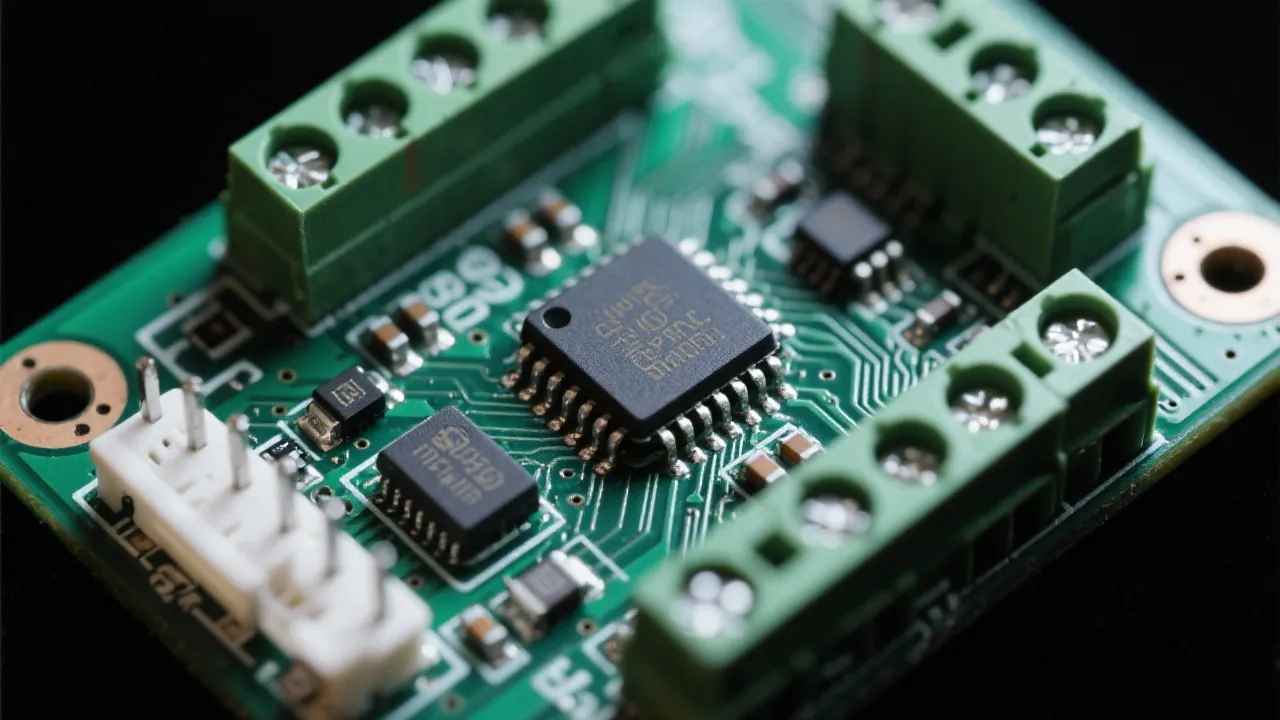

The DRV8704 motor driver is equipped with numerous features that make it an attractive choice for applications ranging from robotics to consumer electronics. Key attributes include its wide voltage range, excellent thermal performance, and advanced safety features. Engineers value its capability to manage various types of loads with precise control, further enhancing its versatility. To explore the benefits it brings to various industries, let's delve deeper into its features:

The DRV8704 is highly applicable in industries where precision motor control is paramount. From automotive to automation sectors, it drives innovation and efficiency. It supports a wide range of motor types including brushed DC motors, stepper motors, and even brushless DC motors, making it a versatile choice for diverse applications. Some main applications include:

| Application Area | Description |

|---|---|

| Robotics | Facilitates intricate movements in robotic arms and machinery. The DRV8704 allows for fluid motion control, essential in robotic applications where precision and repeatability are vital. |

| Consumer Electronics | Enhances performance in devices requiring precision motor control. Examples include printers, scanners, and high-end appliances that use motors for various movements, allowing for improved user experiences. |

| Industrial Automation | Enables advanced motor operations in assembly lines and automated systems. The device supports high-speed operations and can handle multiple motor configurations, making it ideal for complex systems. |

| Automotive Applications | Used for controlling electric actuators in vehicles, enhancing features like power windows, seat adjustments, and climate control systems. |

| Medical Equipment | Powers precision instruments and machinery that require reliable motor control, ensuring patient safety and efficacy in medical procedures. |

For a technical expert, understanding the specifics of the DRV8704 is vital. The driver integrates a mix of high-performance capabilities that cater to rigorous industry standards. Key specifications include:

- Operating Voltage: 8V to 52V - Output Current: Up to 13A - PWM Control: High-frequency PWM for precise motor speed control - Interface: Flexible interface options for seamless integration, including SPI and I2C - Protection Features: Overcurrent, overtemperature, and undervoltage lockout protections - Package Type: Available in an HTQFP package for space-constrained designs

These specifications allow for extensive application in varied environments, ensuring that designers can utilize the DRV8704 within their existing frameworks without extensive redesigns.

Choosing the DRV8704 yields significant advantages, such as increased efficiency and reduced design complexity. Its integration into systems ensures stable performance even under load variances, which is a distinct benefit in dynamic environments. Here are the main benefits:

Implementing the DRV8704 in your project can be simplified by following a structured approach:

What is the primary use of the DRV8704?

The DRV8704 is primarily used for precision motor control in various industrial and consumer applications. Thanks to its adaptable nature, it finds itself at the core of systems needing high reliability and performance.

Can the DRV8704 handle high voltage applications?

Yes, the DRV8704 is capable of handling voltage operations ranging from 8V to 52V. This wide operating voltage makes it suitable for a host of application requirements.

What makes the DRV8704 suitable for industrial applications?

Its robust thermal management and integrated safety features make it ideal for challenging industrial applications. The ability to endure various operational stresses while maintaining high performance boosts its suitability for diverse environments.

Is the DRV8704 easy to integrate into existing systems?

Yes, the DRV8704’s modular design and flexible interface options facilitate its integration into existing systems without requiring major redesigns. This aspect is particularly appreciated by engineers looking to upgrade their systems while maintaining their original designs.

Does the DRV8704 support advanced control methods?

The DRV8704 does support advanced control methods, including programmable microstepping, which allows for smoother transitions and better control over stepper motors. This feature is advantageous in applications that require precision and accuracy, such as 3D printing or CNC machines.

When assessing the DRV8704, it is vital to understand how it compares against other motor drivers available in the market. Many motor drivers have unique specifications and features tailored to specific needs. However, the DRV8704 sets itself apart due to its broad voltage range, integrated safety features, and strong thermal management capabilities. Let’s compare the DRV8704 with some prominent alternatives:

The DRV8833 offers dual H-bridge functionality and is quite popular for driving DC motors and stepper motors. While it has a lower maximum operating voltage (up to 36V) and lower current ratings than the DRV8704, it is often used for less demanding applications. In contrast, the DRV8704 provides higher efficiency, thermal performance, and support for higher output currents.

The TB6600 is widely recognized in stepper motor applications, especially for CNC and 3D printers. It supports microstepping but is bulkier compared to the DRV8704 and often lacks integrated diagnostics or advanced protection features, making the DRV8704 a newer, more technologically advanced option.

The L298N is one of the oldest motor driving circuits and covers both DC motors and stepper motors efficiently. However, with advancements in semiconductor technology, the L298N has drawbacks such as lower efficiency and higher heat generation. The DRV8704 addresses these shortcomings through integrated thermal management and higher operational efficiencies, making it a better modern alternative.

While the DRV8704 excels in many areas, understanding potential challenges when deploying this motor driver is vital. Factors to consider include:

The DRV8704 is a standout choice for professionals looking to enhance motor control in various applications. Its balance of efficiency, reliability, and versatility makes it suitable for both industrial and consumer markets. Understanding its capabilities and integration options can significantly impact system performance and longevity. By considering the specifications and surrounding design aspects, engineers can harness the full potential of the DRV8704 to create innovative solutions across diverse fields.

As automation technology continues to evolve, the demand for advanced motor control solutions like the DRV8704 will only increase, making it a valuable asset for future projects. Continuous innovation in this area will yield even more robust and feature-rich drivers, further enabling a variety of applications and industries to thrive in the competitive technological environment.

Navigating Online Bank Accounts

Understanding AC 380 Systems

Discovering the Tiguan's Versatility

Integrating Usaepay with WooCommerce

Understanding BA 270 Concepts

Understanding AMQ 6209 in Detail

Understanding Hydac RF Filtration Systems

Understanding the BA 270 Course

Navigating the Realm of Business Communication