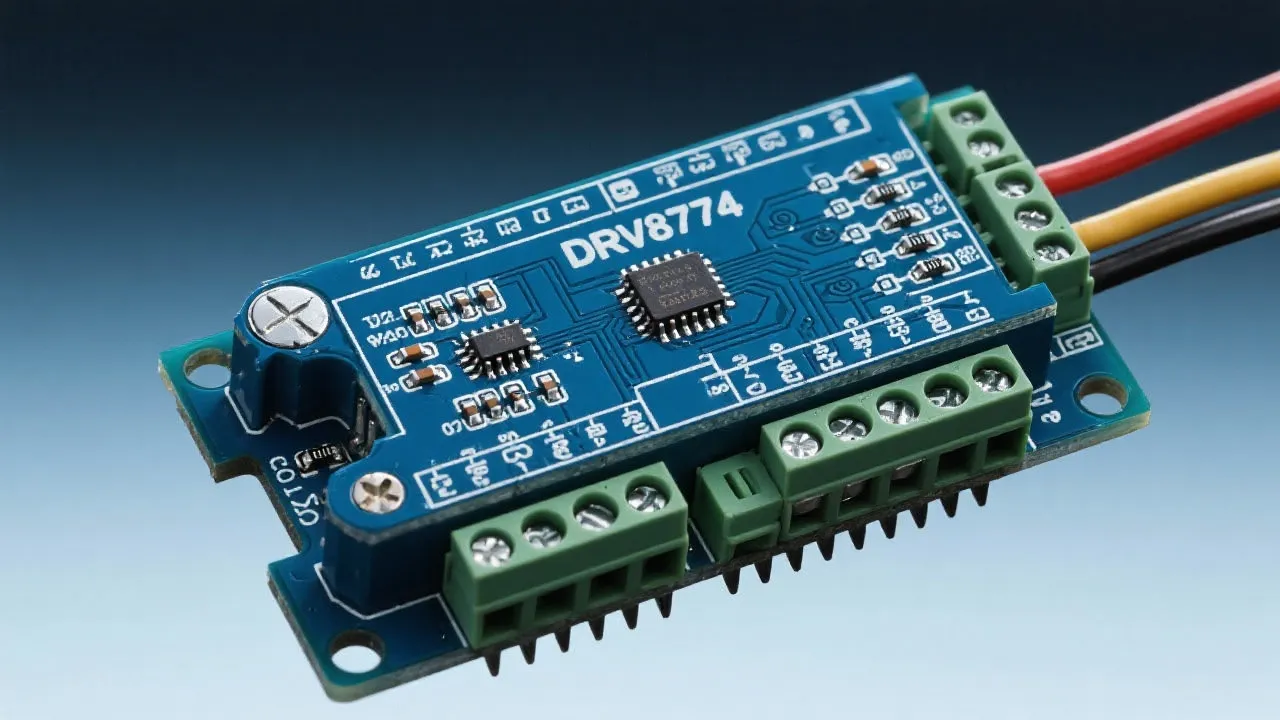

The DRV8704 is a highly advanced motor drive chip specifically designed to enhance the performance of motor applications. It boasts integrated protection features, user-friendly configuration, and high efficiency. This article delves into its technical specifications, optimal use conditions, and critical role in modern technology, aimed at both budding engineers and industry veterans.

The DRV8704 stands out in the realm of motor control technologies due to its advanced features and efficient performance. Manufactured by Texas Instruments, this stepper motor driver is lauded for its ability to precisely control current flow to various motor types, enhancing both performance and reliability in multiple applications. The development of motor control technology has made significant advancements, and devices like the DRV8704 represent the cutting edge of this evolution. In a world increasingly dependent on automation, understanding and utilizing such sophisticated drivers is essential for achieving optimal performance across multiple domains.

The DRV8704 is designed to handle up to 15A peak current and operates within a wide voltage range from 6.5V to 45V, accommodating a diverse array of systems and requirements. It incorporates an innovative current regulation that supports both sensorless and sensor-based control mechanisms, making it exceptionally versatile. This chip also includes micro-stepping capabilities, allowing for smooth motor operation by adjusting to numerous small electrical steps per rotation. This feature is particularly beneficial for applications requiring high precision, such as CNC machines and robotics, where minute adjustments can significantly influence the outcome.

Moreover, the DRV8704 uses a sophisticated PWM (Pulse Width Modulation) control method, which is key in achieving efficient power usage while maintaining the necessary performance. By optimizing the amount of current supplied to the motor, the driver can minimize power loss and heat generation, which is essential for maintaining long-term reliability. Additionally, features such as enhanced safe operating area (SOA) characteristics help prevent thermal issues, enabling the DRV8704 to cool effectively even under heavy load conditions.

The versatility and efficiency of the DRV8704 make it suitable for a myriad of applications across different sectors. In the industrial sector, the DRV8704 finds utility in automated systems, robotics, conveyor systems, and more, where precise control of motor functions is paramount. For instance, in automated assembly lines, the ability to finely adjust motor control can lead to improved throughput and precision in product handling. Additionally, the DRV8704’s compact form factor allows it to be integrated into space-constrained environments, which is common in modern manufacturing setups.

Similarly, in consumer electronics, it enhances performance in applications such as 3D printers and high-performance gadgets that demand precise motor control under varying load conditions. The demand for high-quality 3D prints necessitates accurate control mechanisms, and the DRV8704 fulfills this need effectively, enabling smoother movements and better print resolution. Other notable applications include automation in smart home devices, medical equipment requiring precise motor functions, and electric vehicles, where the driver’s efficiency and reliability play a crucial role in overall performance.

Moreover, the DRV8704 is often utilized in custom robotics projects undertaken by hobbyists and professionals alike. Its capacity to seamlessly integrate with microcontrollers and programmable boards such as Arduino or Raspberry Pi makes it a go-to solution for DIY projects exploring motor control. From robotic arms to autonomous vehicles, the potential applications are limited only by creativity and technical knowledge.

The DRV8704 provides a robust solution for modern motor control needs, featuring high efficiency, vast versatility, and built-in protection mechanisms. Its applications spread across industrial machines to consumer electronics, earning it a place in the toolkit of engineers and tech enthusiasts alike who are looking to maximize performance while ensuring device safety. The continual evolution of motor technology underscores the importance of integrating reliable drivers like the DRV8704 into the design and manufacturing processes. By leveraging its capabilities, developers can create innovative and efficient solutions that meet the demands of today's fast-paced technological landscape.

Moreover, as industries push toward automation and smart technology, the demand for effective motor drivers like the DRV8704 will likely increase, making expertise in this area even more valuable. Beyond mere integration, gaining a deeper understanding of how to optimize the performance of the DRV8704 in various applications will empower engineers to harness its full potential. Transitioning towards more sophisticated automation systems that utilize advanced features of the DRV8704 can lead not just to efficiency gains, but also to a reduction in costs and resource consumption, which is critical in today’s resource-conscious environment.

In conclusion, whether for industrial automation, consumer electronics, or innovative robotics projects, the DRV8704 is an essential component that facilitates the precise control needed for successful outcomes. Embracing the technology offered by the DRV8704 opens the door to various possibilities, allowing users to enhance their designs while enjoying the benefits of technological advancement. As we embark on the future of motor control technology, products like the DRV8704 are set to lead the way, ensuring that engineers have the tools they need to innovate and excel.

Navigating Online Bank Accounts

Understanding AC 380 Systems

Discovering the Tiguan's Versatility

Integrating Usaepay with WooCommerce

Understanding BA 270 Concepts

Understanding AMQ 6209 in Detail

Understanding Hydac RF Filtration Systems

Understanding the BA 270 Course

Navigating the Realm of Business Communication