This article serves as a technical exploration into the Drv8704, a sophisticated output stage for motor control applications. Developed by Texas Instruments, the Drv8704 offers high efficiency and low EMI. This overview provides insight into its technical specifications, benefits, and common applications for better understanding and integration into various motor systems.

In the ever-evolving field of motor control technologies, the Drv8704 stands out as a high-performance driver that caters to complex applications requiring efficient control and minimal electromagnetic interference (EMI). Designed by Texas Instruments, the Drv8704 has gained popularity among engineers and developers due to its versatility and reliability. It is particularly suited for scenarios where precise motor control and low noise are paramount, making it a go-to choice for modern advancements in various industries including robotics, automation, and consumer electronics.

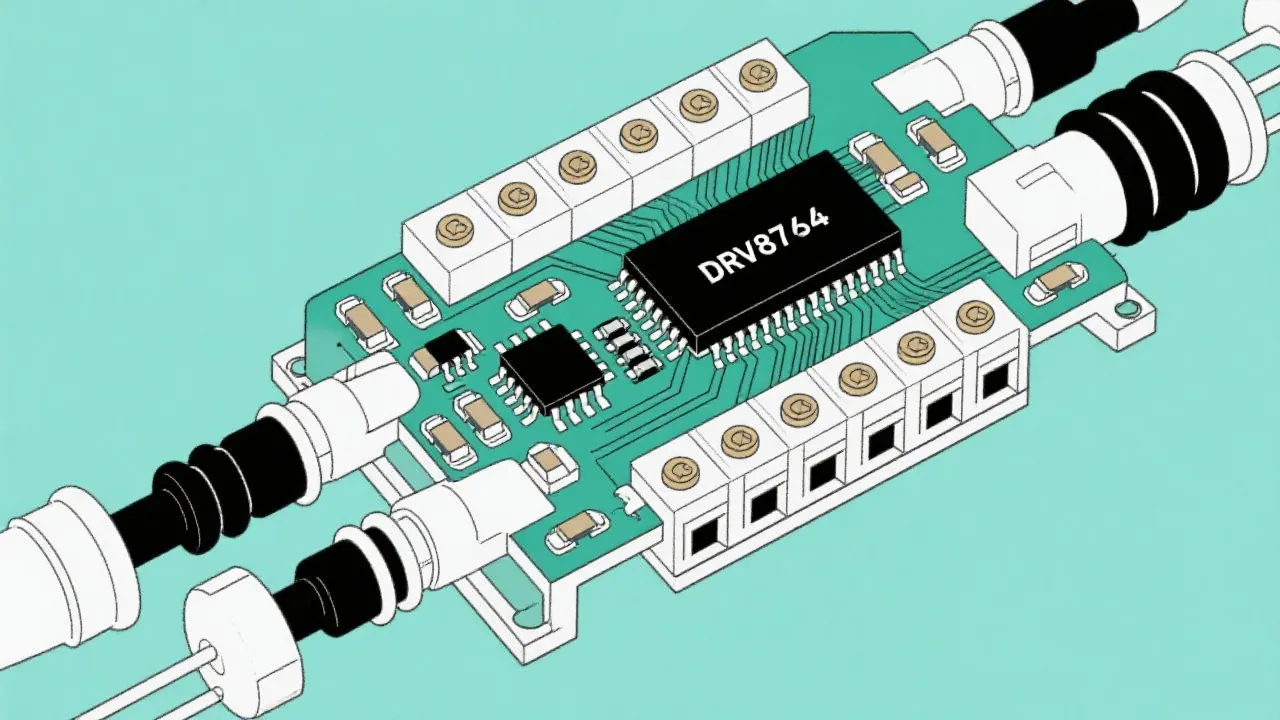

At its heart, the Drv8704 is an integrated motor driver capable of handling PWM (Pulse Width Modulation) frequencies up to 500 kHz, making it suitable for controlling brushed DC motors and solenoids alike. One of the prominent features of this driver is its ability to minimize EMI through adaptive blanking time and various current decay modes. This translates into smoother motor performance and less audible noise during operation, which is particularly important in applications where low noise is a design constraint, such as in home appliances and office equipment.

Moreover, the Drv8704 is engineered with programmable slew rates that allow users to fine-tune the acceleration of the motors, further enhancing the control over mechanical movement. In addition, the device's highly configurable parameters can be adjusted via a Serial Peripheral Interface (SPI), providing substantial flexibility during design and integration processes. This feature is critical for developers looking to optimize performance parameters without needing extensive hardware changes.

Some of the key technical specifications of the Drv8704 include:

These specifications indicate that the Drv8704 is designed to work efficiently in both high-performance and low-power scenarios, reflecting a versatile tool in the engineer's toolkit.

This motor driver provides several advantages that make it an excellent choice for industrial and consumer electronics:

The flexibility and robustness of the Drv8704 make it suitable for a variety of applications, such as:

Industry experts highlight the Drv8704's adaptability as a crucial factor in its widespread adoption. The ability to control different types of motors and solenoids with precision makes it a cornerstone of modern electronic designs. Furthermore, its SPI programmability simplifies integration into existing systems without necessitating extensive re-coding—a significant time-saving advantage for developers. Engineers can particularly appreciate this feature in rapid prototyping environments, where time-to-market is essential.

Additionally, the Drv8704 supports diagnostics and error feedback, which can be invaluable in applications where real-time performance monitoring is required. This aspect aids in fault detection, ensuring that the systems utilizing this driver remain operational and efficient, ultimately lowering maintenance costs across the board.

Moreover, the support community and documentation provided by Texas Instruments further enhance the user experience, allowing engineers to access a wealth of resources. Datasheets, reference designs, and application notes are readily available, making it easier for new users to understand the device’s capabilities and integrate it into their designs successfully.

While the Drv8704 offers several advantages, engineers should take into account specific design considerations when implementing this motor driver into their applications:

In summary, the Drv8704 by Texas Instruments emerges as an exceptional option for motor control applications that demand reliability, efficiency, and customizable control. Its broad voltage range and advanced features streamline motor operations, ensuring optimal performance. Whether in automation, robotics, or consumer electronics, the Drv8704 delivers where it counts very effectively. The combination of its performance characteristics and adaptability makes it a superior choice for developers needing robust solutions in increasingly complex applications.

What is the supply voltage range for the Drv8704?

The Drv8704 operates across a wide supply voltage range from 6.5V to 45V, accommodating various system requirements and allowing designers flexibility in power supply selection.

How does the Drv8704 minimize EMI?

The motor driver minimizes EMI through adaptive blanking time and current decay modes, resulting in smoother performance and reduced noise. In addition, the architecture of the driver is designed to suppress noise generation, making it particularly effective for applications where electromagnetic interference could affect other system components.

Can the Drv8704 be used for solenoids?

Yes, the Drv8704 is versatile enough to control solenoids in addition to brushed DC motors, enhancing its range of applications. This capability is particularly useful in systems requiring precise actuation control, such as in door locking mechanisms and automated dispensing systems.

What are the temperature ranges that the Drv8704 can operate under?

The Drv8704 is designed to operate efficiently over a wide temperature range, generally from -40°C to +125°C, making it suitable for both consumer and industrial applications that may encounter harsh operating conditions.

Are there any specific programming requirements to utilize the SPI interface?

Utilizing the SPI interface requires familiarity with SPI protocols. Developers will need to ensure proper configuration of the microcontroller’s SPI settings to match the Drv8704's requirements, including clock polarity and phase, bit order, and data rate compatibility.

How does the Drv8704's current decay mode impact motor performance?

The choice of current decay mode (slow, fast, or mixed) significantly impacts how quickly the motor can respond to changes in commands. For instance, the fast decay mode can help achieve quick stopping, while the slow decay provides smoother operation, which can be crucial in applications requiring precise control or added safety measures when stopping.

What measures can be taken if the Drv8704 detects an over-current condition?

In the event of an over-current condition, the Drv8704 has built-in safety features that can trigger a shutdown or limit output current to prevent damage. Furthermore, it is advisable to design external provisions such as circuit breakers or fuses to provide additional layers of protection for the entire system.

Are there any suitable alternative motor drivers to the Drv8704?

Yes, there are many alternatives in the market, including ICs like the L298N, DRV8835, and A4988. However, the choice between these alternatives largely depends on the specific requirements of the application, such as current capacity, control methods, and integration complexity.

What kind of diagnostic features does the Drv8704 offer?

The Drv8704 incorporates a variety of diagnostic features, including real-time current sensing and fault detection signals. Users can leverage these features for performance monitoring, helping to maintain system health and preemptively address potential issues before they escalate.

Navigating Online Bank Accounts

Understanding AC 380 Systems

Discovering the Tiguan's Versatility

Integrating Usaepay with WooCommerce

Understanding BA 270 Concepts

Understanding AMQ 6209 in Detail

Understanding Hydac RF Filtration Systems

Understanding the BA 270 Course

Navigating the Realm of Business Communication